Chuck D. Bones

Circuit Wizard

Check resistor values too. Easy to misread the color bands.

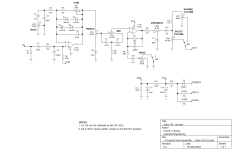

If you'd like me to design a board for you in this configuration lemme know.Hmm. I will check connections.

I really like the addition of the double pot and the toggle.

Two versions of the circuit could be made. This one as the deluxe version, and then a simpler version. Perhaps just bass, mid, and treble, with volume, gain and drive. Discuss that at another time.

I like the idea of putting this in a 1590BB2

Turned tall.7 knobs, a toggle and two footswitches. Maybe the 4 band EQ all in one row. Everything else in the other.

One footswitch to put it in the chain and one that bypasses the drive to a resistor to equal the R7 and removes the VR8 volume boost limit as well.

I think the low parts count and high knob count is a good landing spot -- it is more or less the OD equivalent of the fuzz foundry. I like sticking with the IR leds as well instead of adding switches for other clippers.Lol. No kidding. I do have a disease called "can't well enough alone-itis". I would wager several of us do here on the forum...lol

I originally just wanted to toggle switch for a mid cut to the original circuit just to get different tones. And then we started looking at tone stacks. Then Chuck came up with this and I thought oh man I do like having a presence knob.

I stated earlier I thought about making a simplified version as well. maybe just a six nom version with tmb tone stack. And one foot switch. But that would require a difference schematic to go off of for a different circuit board and design it to be in a 125b.

Fingers crossed we get a Boneyard Bosch front load washing machine project soon... My Maytag has seen better days...Had to replace one of the solenoid valves and that's about it.