finebyfine

Well-known member

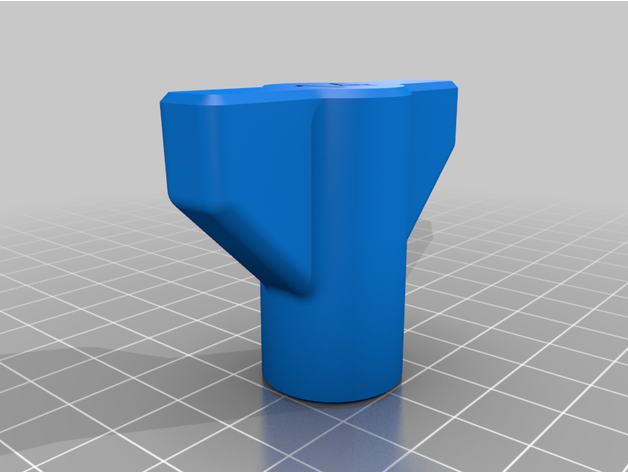

Some of my most used rocket sockets (plastic non marring nut drivers: https://lovemyswitches.com/rocket-sockets-pedal-building-socket-set/) are pretty worn down. They’ve lasted me a long time and much longer than I would have assumed. But because I really only use 3 sizes, I was wondering if anyone’s ever restored them?

I’m considering either sawing off 1/4 inch where they’re worn or hitting them with some heat while they’re on a nut they fit. I’ll probably buy a new set anyway so there’s really nothing to lose. If anyone’s done similar I’d appreciate the insight!

I’m considering either sawing off 1/4 inch where they’re worn or hitting them with some heat while they’re on a nut they fit. I’ll probably buy a new set anyway so there’s really nothing to lose. If anyone’s done similar I’d appreciate the insight!