Idroj

Active member

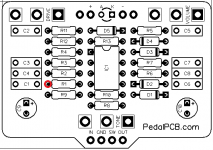

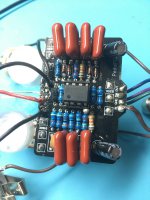

Hi, I built this Blue Breaker and I have been trying to troubleshoot it with no luck. One time, only one time, I somehow got it to work for a moment and I enjoyed the hell out of it for 3-4 minutes only, sadly.

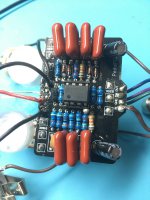

As you will see, I probably ordered wrong types of caps, please don't laugh, lol...

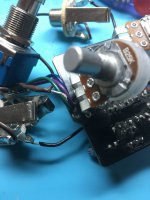

LED lights up upon switching on but no sound. When I bypass, LED still lights up but only faintly. Sound goes through bypass just fine.

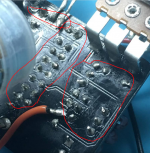

I learned that I should clean the back of pcbs with IPA today on a previous post, maybe I should start right there?

Any help would be appreciated, thanks.

As you will see, I probably ordered wrong types of caps, please don't laugh, lol...

LED lights up upon switching on but no sound. When I bypass, LED still lights up but only faintly. Sound goes through bypass just fine.

I learned that I should clean the back of pcbs with IPA today on a previous post, maybe I should start right there?

Any help would be appreciated, thanks.