BuddytheReow

Breadboard Baker

Hey Folks,

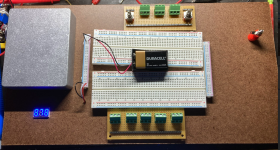

I'd rather just write my thoughts down than lose sleep over this. My original breadboard was 2 breadboards mounted on a few pieces of cardboard. Then a protoboard fell into my lap last year. An excellent upgrade indeed! The protoboard is great, but I think it needs some additional tasty goodies.

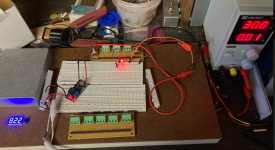

@fig was kind enough to give me a bench power supply to REALLY start tinkering with some circuit legos and unleash my inner mad scientist!

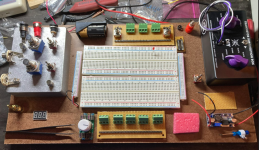

So....I think it's time to make my own "ultimate" protoboard. Don't get me wrong; I loooooove a good solder session! It's actually quite therapeutic for me to shut my brain off for a while and not think about the outside world. Here's what I'm thinking.

The protoboard uses 2 800-hole breadboards. I rarely use the second one for builds so I think this is a good amount or real estate. Any more and it's overkill and will take up too much space on my bench. I have to store it somewhere, ya know?

I need to connect the bench power supply to my board. But, I also need to have a DC power plug for a battery or to steal from my pedalboard's power supply if needed. I want it controlled with a switch and have a LED indicator to tell me which power supply I'm using.

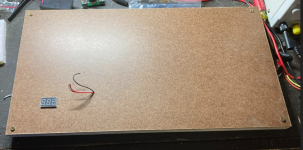

Fig also sent me a digital voltage meter display. Here's an example of one:

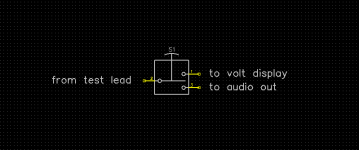

https://www.amazon.com/gp/product/B079N98PY4/ref=ox_sc_act_title_2?smid=A30QSGOJR8LMXA&psc=1 I can use this to test voltages on certain components. I'd have to get a probe too and control it with a switch. Maybe later if I'm using just 9v input such as a battery I may want to utilize a charge pump or step down converter for other voltages.

Audio signal will be a separate section. I want a switch attached to an audio probe for further testing. Could I just use the output jumper? Sure, but I'm dreaming here and I want it!!! I would have to ground the enclosure to mount the in/out jacks.

I have some bluetooth chips. Should I make input/output bluetooth compatible? On the fence right now.

I don't have metalwork tools or experience, so this is going to be mounted on wood. Maybe not a single piece since I may need to hide some grounding wires/jumpers underneath, so I think I'll put a thin top. I may paint the darned thing once I'm done.

If anyone else has some ideas just let me know!

BuddytheReow

I'd rather just write my thoughts down than lose sleep over this. My original breadboard was 2 breadboards mounted on a few pieces of cardboard. Then a protoboard fell into my lap last year. An excellent upgrade indeed! The protoboard is great, but I think it needs some additional tasty goodies.

@fig was kind enough to give me a bench power supply to REALLY start tinkering with some circuit legos and unleash my inner mad scientist!

So....I think it's time to make my own "ultimate" protoboard. Don't get me wrong; I loooooove a good solder session! It's actually quite therapeutic for me to shut my brain off for a while and not think about the outside world. Here's what I'm thinking.

The protoboard uses 2 800-hole breadboards. I rarely use the second one for builds so I think this is a good amount or real estate. Any more and it's overkill and will take up too much space on my bench. I have to store it somewhere, ya know?

I need to connect the bench power supply to my board. But, I also need to have a DC power plug for a battery or to steal from my pedalboard's power supply if needed. I want it controlled with a switch and have a LED indicator to tell me which power supply I'm using.

Fig also sent me a digital voltage meter display. Here's an example of one:

https://www.amazon.com/gp/product/B079N98PY4/ref=ox_sc_act_title_2?smid=A30QSGOJR8LMXA&psc=1 I can use this to test voltages on certain components. I'd have to get a probe too and control it with a switch. Maybe later if I'm using just 9v input such as a battery I may want to utilize a charge pump or step down converter for other voltages.

Audio signal will be a separate section. I want a switch attached to an audio probe for further testing. Could I just use the output jumper? Sure, but I'm dreaming here and I want it!!! I would have to ground the enclosure to mount the in/out jacks.

I have some bluetooth chips. Should I make input/output bluetooth compatible? On the fence right now.

I don't have metalwork tools or experience, so this is going to be mounted on wood. Maybe not a single piece since I may need to hide some grounding wires/jumpers underneath, so I think I'll put a thin top. I may paint the darned thing once I'm done.

If anyone else has some ideas just let me know!

BuddytheReow