vigilante398

Authorized Vendor

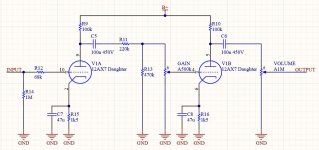

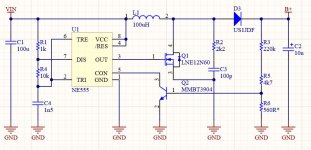

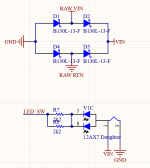

I think this is officially the first pedal build I've posted on here, but I've been building for a while. Most of my builds for the past couple years have been SMD, but all the amps I build are turretboards, so I got the idea to mix the two, and I do these as a limited run every now and then. Space Heater is a simple tube preamp, the SMD version uses 250V caps so I limit B+ to 235V, but on these I use 400V caps so I've upped B+ to 360V, and it sounds FABULOUS. I hide all the SMD stuff for the nixie-style power supply on the bottom of the board so it doesn't detract from the "mojo". CNC milling, powdercoating, and laser engraving/cutting of the faceplate were done by me in my garage, UV printing on the bottom plate was done by me in my basement. SMD soldering is a mix of pick-and-place and hand-soldering as the board house ran out of some of the components I need for the nixie supply.

Happy to answer any questions

Happy to answer any questions