Chuck D. Bones

Circuit Wizard

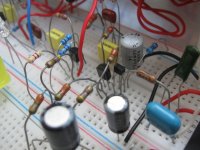

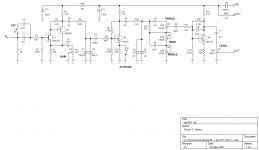

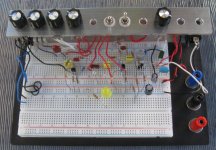

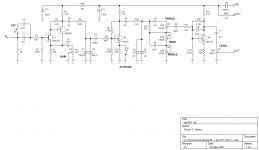

I've been fooling around with FET Overdrive circuits that use Germanium diodes for clipping off and on for a few weeks now. I've finally arrived at something that I like. I might try some alternate tone stacks, although this one works pretty well. This started out as a four stage overdrive with three hard clippers, but I felt it was a bit much. Some of you might like it that way. Up front is a Sziklai gain stage. Q1 needs to be low-capacitance so it doesn't muffle the pickups. I used a 2SK193, but a J201 would also work. Fiddle R6 to get about 5V on Q2-E. Q1 & Q2 drive the first hard clipper (D1 & D2). Use whatever germanium diodes you like, low leakage is preferable, but not mandatory. I deliberately keep the impedance in that part of the circuit low to accommodate diode leakage. The ATTITUDE switch kicks the 2nd-stage gain up by 16dB. With the ATTITUDE set for Mellow, D1 & D2 do all of the clipping; Q3 barely tickles LEDs D3 & D4. Set the ATTITUDE to Kerfuffle and the LEDs light up. It pops a bit when you switch the ATTITUDE switch. It's not intended to be an on-demand boost. The LEDs are followed by a Fender-style tone stack. I left one of the caps out because DC blocking is not required in this circuit. The last stage provides gain recovery after the tone stack and a low-impedance output. Q4's gain is set so it will not saturate for any control setting. The FAT switch does the usual thing, it tightens the bass so you can drive this with humbuckers and not get too muddy. Unless you want to. Between the GAIN control and the ATTITUDE switch, you can easily dial-in the desired amount of dirt and then control it from the guitar. It's still a work in progress, but it's close enough to done that I wanted to share it.

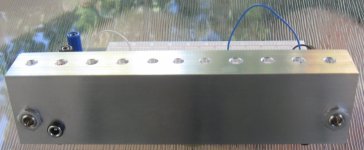

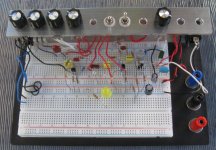

Left to right: Volume, Bass, Mid, Treble, Attitude, Fat, Gain. The Ge diodes are under the switches. The red LEDs are in the middle of the board.

Bonus topic:

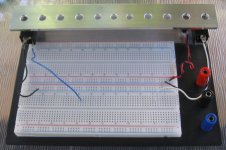

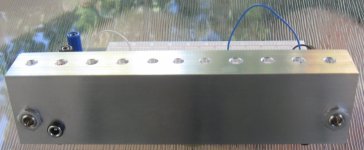

I bought some breadboards on eBay, picked up some scrap aluminum at the local metal yard, did a little cutting and drilling. Voilà! Three more breadboards. The panel has enough holes for eight pots and three toggle switches. The binding posts came with the breadboard and can be used to hook up aux power.

Left to right: Volume, Bass, Mid, Treble, Attitude, Fat, Gain. The Ge diodes are under the switches. The red LEDs are in the middle of the board.

Bonus topic:

I bought some breadboards on eBay, picked up some scrap aluminum at the local metal yard, did a little cutting and drilling. Voilà! Three more breadboards. The panel has enough holes for eight pots and three toggle switches. The binding posts came with the breadboard and can be used to hook up aux power.

Last edited: