As far as I can work out your VREF should be 4.89v coming from your voltage divider R101 and 102

I wouldn't think 0.11v would mis bias it too much

I'd do what

@Chas Grant says as a quick check swap your op amp from your working circuit to this one

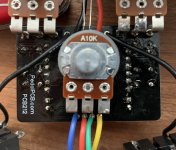

All your components I can see look to be the correct value and orientation, can't see the drive pot value or volume pot and a few caps

I'd guess it's something in the feedback loop throwing it out with you saying the drive pot affects it

You could check your drive pot changes resistance as you turn it - all the way down between 1 and 3 should be in ohms and all the way up K ohms, you won't get totally accurate readings it being in circuit but you'll be able to check resistance varies as you turn it

It's A taper so in the mid position it's only around 40 to 60K a tenth of the resistance give or take it's tolerance + or - 20% so shouldn't really be full gain farting

I'm guessing here not having it in front of me, but this is what I'd check, it's quite often a process of elimination once you've done your visual checks

It may well be a faulty drive pot but I think you're better trying to find out before you start removing components especially board mounted stuff

Check your drive pot first then

I'd continuity check and or reflow components in and around the feedback loop C7, D2 to 6, R9, the drive pot, R11, 12, C5 and 6 all you need to do is hold your iron on the solder joints for around 3 or 4 seconds until it flows nicely, you need to be careful with the diodes they can be damaged by heat so 4 seconds on one side, let it cool then reflow the other side