Audandash

Well-known member

Okay so you would think I would know this stuff since I have 10+ years pedal building experience but I just always followed the rules I learned at the beginning and never really asked questions. I am at the point now where I want to know. Could I search online? Sure. I don't really want to though since I will find information on caps for auto use and other stuff I am not going to use them for etc.. I want to know for our specific purposes, audio circuits. I also thought I would ask because it may help someone just getting started or an old timer like me in some cases. What brought me to this point is the Aionfx Amethyst (Boss DM-2). It has the standard build or you can do an Aqua Puss variant. It just has different values or components. So the question’s are about changing some of the 1uf caps to 10uf caps. Most of the 1u’s are film but when you change it to 10u its electrolytic. Please keep in mind I really want to know the answers as it pertains to audio circuits only not just in general. Here are the questions:

What is the difference in audio grade electrolytic vs standard? It’s not a tolerance thing so it must be something else. Different electrolytic solution in the cap maybe? What makes it audio grade besides a fancy colored package?

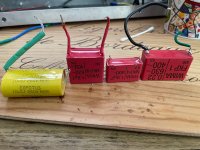

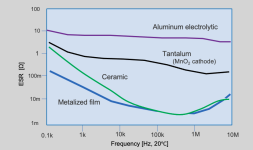

Size and price is obviously a huge factor making a 10u poly cap prohibitive. I learned you should use poly in an audio path vs electrolytic if possible. Why is that so? Is it just because an electrolytic cap won’t stay in spec as long or is it something else?

On a handful of pedalpcb boards and some others i have seen instead of using film for 1u caps mlcc caps are used. I know this is done for size but they are usually a little cheaper so why don’t more designs use them? In my experience mlcc was generally used for lower pf values and sometimes for power filtration (100nf cap thats become common). Is there soemthing wrong with using them in an audio path?

Lastly, mlcc now has a variation I see called x7r. Are the x7r the same as standard mlcc or are they different in some manner.

Thanks in advance

What is the difference in audio grade electrolytic vs standard? It’s not a tolerance thing so it must be something else. Different electrolytic solution in the cap maybe? What makes it audio grade besides a fancy colored package?

Size and price is obviously a huge factor making a 10u poly cap prohibitive. I learned you should use poly in an audio path vs electrolytic if possible. Why is that so? Is it just because an electrolytic cap won’t stay in spec as long or is it something else?

On a handful of pedalpcb boards and some others i have seen instead of using film for 1u caps mlcc caps are used. I know this is done for size but they are usually a little cheaper so why don’t more designs use them? In my experience mlcc was generally used for lower pf values and sometimes for power filtration (100nf cap thats become common). Is there soemthing wrong with using them in an audio path?

Lastly, mlcc now has a variation I see called x7r. Are the x7r the same as standard mlcc or are they different in some manner.

Thanks in advance