Alan W

Well-known member

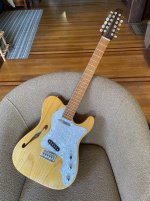

I'll start with a picture.

Up until about 2 months ago, this was a Baritone I had put together in 2020. In late 2021 I began to think how much I'd love a guitar that combined the open and rich sound of my Eastman carve stop (thin line, single-cut jazz box basically) with the Tele Baritone I had made. I found someone to make me one, which took from Feb 22 to early July, about 6 weeks ago. Right before it was done, I decided I really didn't need 2 Baritones, so I thought I'd convert it to a 12 string. I was bummed initially, because Warmoth only gets to 1 3/4 inch nuts on their 12s, (and that's what I like on my regular 6s). After a few days of looking around (no idea why it took so long!) I found Musikraft (I thought they were no longer in business) and they have 1 7/8 as a stock option! So, I went with that, on a fairly fat (but not as fat as my normal '59 carve, I mean, there's just so much wideness and fatness you can do, right? neck that's wedge with a roasted birdseye fretboard, and my favorite Jascar EVO wire. (I have a bass with a wedge neck, that is just waxed, and really love its feel—plus wedge is a lower midrange neck wood, (much like mahogany) so it would help mitigate the extra treble from a 12. (Then the maple adds some sparkle to the top—at least that was the plan.)

So this has just been strung up this afternoon, and I figure it'll be a day before everything is stabile enough for me to start tweaking the set up, which I largely guess at (I mean, like I just adjusted heights and intonation of the saddles by eye before stringing it up, and took a complete guess at how much to spin the truss rod. It's staying nicely in tune, doesn't buzz, and right now has action (other than the first two frets) that' I'd be completely happy with. Intonation is playable, but three of the pairs need tome adjustment. (The Gotoh has 6 "double saddles" that can be moved independently, so you can get each string intoned; I think this is great for an electric 12. In any case, I'm really not planning on playing it tonight— I'll do the real set up tomorrow and then have at it. Just listened to it straight into the amp so far, and everything works pretty much as it should.

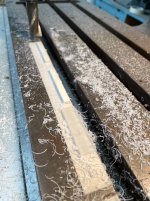

The Musikaft neck was just superb—I was a bit disappointed when I measured it, and it DIDN"T NEED ANY FRETWORK, AT ALL! Even the upper fret drop off was there, and I couldn't find any hint of rock with my fret rockers. Since I have a background in prototype machining, I have tools (even around home) that allow me to take really accurate measurements.

Edited: read "wenge" every time you see the neck wood described as "wedge." grrr...

While I was waiting for the neck (took about 4 weeks, 5 with shipping) I ordered the other parts I'd need: initially just a bone nut blank and a Tele 12 string bridge. The bridge came in and really was a piece of crap, so I sent it back and ordered a slightly different one. Since the main problem with the first bridge was how poor the saddles were, I also ordered a Gotoh 12 string bridge, figuring I could possibly use the saddles from that on the tele style bridge.

The second tele bridge came in, slightly different, but just as horrid as the first (I mean, not being able to cleanly adjust the intonation on a 12 string is a quick path to mental illness.) And, the saddle widths were slightly different than the Gotoh saddles, so there's be .015 gaps between them. (I did think about shims, and rejected it. I've had real issues with bridges that had any vibration in them, and fully wanted to avoid this. So, in using the Gotoh bridge, I now needed to order a new pickgaurd too!

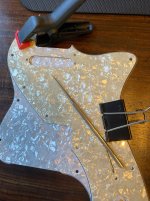

At first, I thought I'd design and make my own—draw it up, laser cut a piece of 1/2 inch Medite and route a blank I bought. But, I've been enjoying the notion of doing as much by hand as possible, or at least practical, and I could buy an almost ready pickguard for about $20 more than just the material. The only catch was that I'd have to cut the PU holes in it.

But, the main issue with using the Gotoh bridge was that it placed the 6 string through body strings in a different location that the normal tele bridge, and I didn't want to move the ferrules. As a matter of fact, I wanted to make this transformation completely reversible.

I'll add a series of posts that describe in more detail what each of these steps involved, or at least what my solutions for therm were. Now, off to play my Baritone!

Up until about 2 months ago, this was a Baritone I had put together in 2020. In late 2021 I began to think how much I'd love a guitar that combined the open and rich sound of my Eastman carve stop (thin line, single-cut jazz box basically) with the Tele Baritone I had made. I found someone to make me one, which took from Feb 22 to early July, about 6 weeks ago. Right before it was done, I decided I really didn't need 2 Baritones, so I thought I'd convert it to a 12 string. I was bummed initially, because Warmoth only gets to 1 3/4 inch nuts on their 12s, (and that's what I like on my regular 6s). After a few days of looking around (no idea why it took so long!) I found Musikraft (I thought they were no longer in business) and they have 1 7/8 as a stock option! So, I went with that, on a fairly fat (but not as fat as my normal '59 carve, I mean, there's just so much wideness and fatness you can do, right? neck that's wedge with a roasted birdseye fretboard, and my favorite Jascar EVO wire. (I have a bass with a wedge neck, that is just waxed, and really love its feel—plus wedge is a lower midrange neck wood, (much like mahogany) so it would help mitigate the extra treble from a 12. (Then the maple adds some sparkle to the top—at least that was the plan.)

So this has just been strung up this afternoon, and I figure it'll be a day before everything is stabile enough for me to start tweaking the set up, which I largely guess at (I mean, like I just adjusted heights and intonation of the saddles by eye before stringing it up, and took a complete guess at how much to spin the truss rod. It's staying nicely in tune, doesn't buzz, and right now has action (other than the first two frets) that' I'd be completely happy with. Intonation is playable, but three of the pairs need tome adjustment. (The Gotoh has 6 "double saddles" that can be moved independently, so you can get each string intoned; I think this is great for an electric 12. In any case, I'm really not planning on playing it tonight— I'll do the real set up tomorrow and then have at it. Just listened to it straight into the amp so far, and everything works pretty much as it should.

The Musikaft neck was just superb—I was a bit disappointed when I measured it, and it DIDN"T NEED ANY FRETWORK, AT ALL! Even the upper fret drop off was there, and I couldn't find any hint of rock with my fret rockers. Since I have a background in prototype machining, I have tools (even around home) that allow me to take really accurate measurements.

Edited: read "wenge" every time you see the neck wood described as "wedge." grrr...

While I was waiting for the neck (took about 4 weeks, 5 with shipping) I ordered the other parts I'd need: initially just a bone nut blank and a Tele 12 string bridge. The bridge came in and really was a piece of crap, so I sent it back and ordered a slightly different one. Since the main problem with the first bridge was how poor the saddles were, I also ordered a Gotoh 12 string bridge, figuring I could possibly use the saddles from that on the tele style bridge.

The second tele bridge came in, slightly different, but just as horrid as the first (I mean, not being able to cleanly adjust the intonation on a 12 string is a quick path to mental illness.) And, the saddle widths were slightly different than the Gotoh saddles, so there's be .015 gaps between them. (I did think about shims, and rejected it. I've had real issues with bridges that had any vibration in them, and fully wanted to avoid this. So, in using the Gotoh bridge, I now needed to order a new pickgaurd too!

At first, I thought I'd design and make my own—draw it up, laser cut a piece of 1/2 inch Medite and route a blank I bought. But, I've been enjoying the notion of doing as much by hand as possible, or at least practical, and I could buy an almost ready pickguard for about $20 more than just the material. The only catch was that I'd have to cut the PU holes in it.

But, the main issue with using the Gotoh bridge was that it placed the 6 string through body strings in a different location that the normal tele bridge, and I didn't want to move the ferrules. As a matter of fact, I wanted to make this transformation completely reversible.

I'll add a series of posts that describe in more detail what each of these steps involved, or at least what my solutions for therm were. Now, off to play my Baritone!

Last edited: