aquataur

Member

I did not find a thread that this question would fit in so I opened a new one.

Admin please move if in the wrong section.

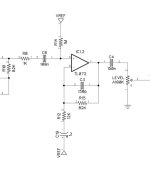

I just looked through the Cattle Driver schematic. I noticed that C19, which is in the ground leg of the output stage's feedback node, appears in the wrong polarity.

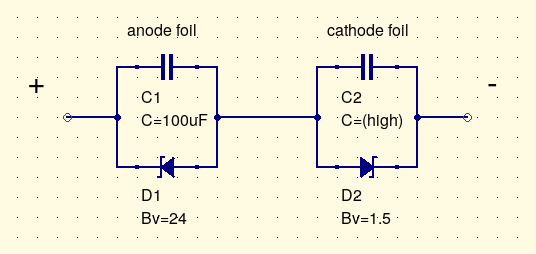

If the reference were GND, then it would certainly be the wrong way around. Since it is referenced to Vref, theoretically there is no DC across it, which raises the question, if the electrolytic functions properly.

Some designers use as reference Vref. Does somebody know if there is a genuine reason for this?

Theoretically, Vref is a hard rail, but it isn't really. I would use GND and flip the cap around.

The picture shows a fragment of the "official" pdf.

Any insights?

Edit: just saw that the (-) side of C11 has no DC reference either. Theoretically, an electrolytic cap in such a situation will not format its electrolytic properly.

Admin please move if in the wrong section.

I just looked through the Cattle Driver schematic. I noticed that C19, which is in the ground leg of the output stage's feedback node, appears in the wrong polarity.

If the reference were GND, then it would certainly be the wrong way around. Since it is referenced to Vref, theoretically there is no DC across it, which raises the question, if the electrolytic functions properly.

Some designers use as reference Vref. Does somebody know if there is a genuine reason for this?

Theoretically, Vref is a hard rail, but it isn't really. I would use GND and flip the cap around.

The picture shows a fragment of the "official" pdf.

Any insights?

Edit: just saw that the (-) side of C11 has no DC reference either. Theoretically, an electrolytic cap in such a situation will not format its electrolytic properly.

Attachments

Last edited: