You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sag control on basic fuzz face

- Thread starter ac30irons

- Start date

Feral Feline

Well-known member

Yes, it is doable.

There are a number of ways to it being doable, but I'll suggest taking a look at the Chop Shop (Barbershop).

Check the Fuzz Foundry as well.

There are a number of ways to it being doable, but I'll suggest taking a look at the Chop Shop (Barbershop).

Check the Fuzz Foundry as well.

Thanks for the reply. I can see it’s putting B10K in but where and how would I implement that on the fuzz face ?Yes, it is doable.

There are a number of ways to it being doable, but I'll suggest taking a look at the Chop Shop (Barbershop).

Check the Fuzz Foundry as well.

MobyOctopad

Active member

I'll preface this by saying I'm never sure what I'm doing when it comes to the hobby, but could you add the pot at the end of the power section like Aion does in their take on the Fuzz Factory? Assuming you were thinking of adding it to an NPN Fuzz Face; not sure how different things would be dealing with a voltage inverter if you had a PNP build in mind.

All that said, I'd wait for someone who actually knows what they're doing to weigh in.

All that said, I'd wait for someone who actually knows what they're doing to weigh in.

Last edited:

Dude, I have no ideaI'll preface this by saying I'm never sure what I'm doing when it comes to the hobby, but could you add the pot at the end of the power section like Aion in their take on the Fuzz Factory? Assuming you were thinking of adding it to an NPN Fuzz Face, not sure how different things would be dealing with a voltage inverter if you had a PNP build in mind.

All that said, I'd wait for someone who actually knows what they're doing to weigh in.

Feral Feline

Well-known member

Thanks for the reply. I can see it’s putting B10K in but where and how would I implement that on the fuzz face ?

The Fuzz Foundry is like a Factory-made Fuzz Face; so use that as your template.

Are you building your FF on a PCB, vero, perf, tagboard, PtoP?

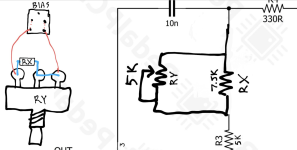

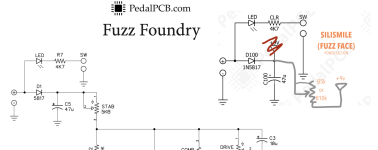

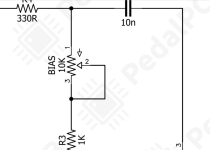

I'll use Robert's Foundry and SiliSmile schematics to illustrate:

Using the Fuzz Foundry as an example to building SAG into your SiliSmile:

- Lift one end of each D100 and C100, the ends that meet, ie don't solder those ends to the board, just the ends that go to power-input and ground respectively;

- solder the diode and caps loose ends with a wire together,

- other end of wire goes to your pot SAG's lug-1 & jumper lug-1 to lug-2.

- solder a wire from SAG lug-3 back to the remaining pad for D100 (or C100, whichever is more convenient).

- Fire up the board (you've already populated/soldered with all components jacks pots etc) and congratulate yourself on having added a SAG pot.

You could also omit C100 from the board entirely and solder one end of it to lug 1 or 2 of SAG and the other end to ground.

For that matter you could run D100 direct from the DC jack to the SAG lug-1 (or lug-2, since 1&2 lugs are jumpered), and not bother populating

D100 nor C100 on the board at all...

OR

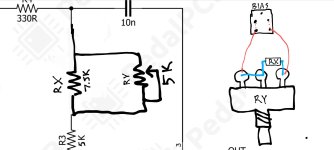

As described above, but instead of D100 & C100, lifting the ends of R2 & R4 of the SiliSmile (see the build doc for full schematic).

You'll need to set your DMM to Batfink-Beep mode to determine which is the correct end of the components you want to lift. (I don't have the PCB to check myself)

Looking at the diagram above, I'd personally choose running D100 straight from the power-jack to the SAG pot lug-1&2 and a wire from lug-3 to the square pad of D100. ( and C100 can stay where it is ).

Yeah, there's a million ways to skin a cat, but often the simplest is best.

Leave D100 off the board and run it from the DC jack to the SAG pot and the output of the SAG to the board's D100 square-pad (make sure you've oriented the diode correctly ie stripey-end connects to the pot).

Feral Feline

Well-known member

I'll preface this by saying I'm never sure what I'm doing when it comes to the hobby, but could you add the pot at the end of the power section like Aion does in their take on the Fuzz Factory? Assuming you were thinking of adding it to an NPN Fuzz Face; not sure how different things would be dealing with a voltage inverter if you had a PNP build in mind.

All that said, I'd wait for someone who actually knows what they're doing to weigh in.

Neither am I sure of anything, but you can see my thought process in my post above to arrive at a simple solution.

The only thing being fed power is R2 & R4, yet I was pulling this and that when all that was needed messing with was D100.

For a PNP build with an inverter, you'd have to put the SAG pot AFTER the inverter/charge-pump.

However, I don't know how the SAG would affect the load on the charge-pump.

Would it burn the pump? Should the SAG as rheostat be rewired to voltage splitter with excess volts dumped to ground? I don't know, but the info is probably already out there, if not on this forum then on DIYStompboxes or Freestompboxes or electronicstackexchange etc.

Last edited:

Thanks for all your help. I’m using a simple fuzz face pcd but not from pedal pcb. The V+ is on the break out board.The Fuzz Foundry is like a Factory-made Fuzz Face; so use that as your template.

Are you building your FF on a PCB, vero, perf, tagboard, PtoP?

I'll use Robert's Foundry and SiliSmile schematics to illustrate:

View attachment 78837

Using the Fuzz Foundry as an example to building SAG into your SiliSmile:

- Lift one end of each D100 and C100, the ends that meet, ie don't solder those ends to the board, just the ends that go to power-input and ground respectively;

- solder the diode and caps loose ends with a wire together,

- other end of wire goes to your pot SAG's lug-1 & jumper lug-1 to lug-2.

- solder a wire from SAG lug-3 back to the remaining pad for D100 (or C100, whichever is more convenient).

- Fire up the board (you've already populated/soldered with all components jacks pots etc) and congratulate yourself on having added a SAG pot.

You could also omit C100 from the board entirely and solder one end of it to lug 1 or 2 of SAG and the other end to ground.

For that matter you could run D100 direct from the DC jack to the SAG lug-1 (or lug-2, since 1&2 lugs are jumpered), and not bother populating

D100 nor C100 on the board at all...

OR

As described above, but instead of D100 & C100, lifting the ends of R2 & R4 of the SiliSmile (see the build doc for full schematic).

You'll need to set your DMM to Batfink-Beep mode to determine which is the correct end of the components you want to lift. (I don't have the PCB to check myself)

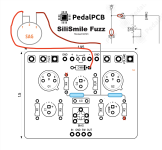

View attachment 78839

Looking at the diagram above, I'd personally choose running D100 straight from the power-jack to the SAG pot lug-1&2 and a wire from lug-3 to the square pad of D100. ( and C100 can stay where it is ).

Yeah, there's a million ways to skin a cat, but often the simplest is best.

Leave D100 off the board and run it from the DC jack to the SAG pot and the output of the SAG to the board's D100 square-pad (make sure you've oriented the diode correctly ie stripey-end connects to the pot).

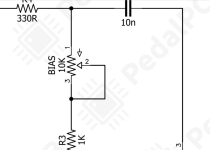

View attachment 78840

Note: when. Towing legs of a pot together to use a a variable resistor, I will do it wrong/backwards 97.36% of the time. So, take this fact into account and test it on a breadboard or get info from someone who can work out left right mentally without physically breaking things.

Ok---

Great write up FF. I'll add in that if you want to bring the bias to the front panel, you may want to find the usable range and wire it accordingly.

Using the Silismile as an example again.

Say, the usae range of the bias trimmer is 4k to 7k. Well, you have a 1k resistor in series already so your total bias resistance that has desirable sound is 5k-8k.

Our biggest restriction in doing this is fixed pot value.

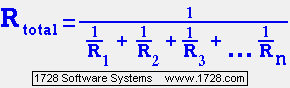

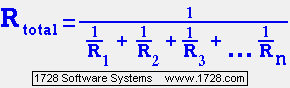

You can modify R3 to your minimum usable resistance. Now you'll need to figure out parallel resistances to get 3k in series with R3. There's a formula, or a billion free calculators. Going with a 5k pot, adding a 7.5k resistor in parallel with our 5k pot gives us a net max parallel resistance of 3k. As the pot is turned the equivalent resistance decreases.

Now, changing the value of one resistor and adding another onto the back of your pot, you now have a bias control with a fully functional range of sweep(instead of 1/3 of it making sound.

It does take a little bit more thought and planning, but not much more work that bringing it to the front panel.

To reiterate, have someone double check my bridging and leg selection. It's probably backwards

Ok---

Great write up FF. I'll add in that if you want to bring the bias to the front panel, you may want to find the usable range and wire it accordingly.

Using the Silismile as an example again.

Say, the usae range of the bias trimmer is 4k to 7k. Well, you have a 1k resistor in series already so your total bias resistance that has desirable sound is 5k-8k.

Our biggest restriction in doing this is fixed pot value.

You can modify R3 to your minimum usable resistance. Now you'll need to figure out parallel resistances to get 3k in series with R3. There's a formula, or a billion free calculators. Going with a 5k pot, adding a 7.5k resistor in parallel with our 5k pot gives us a net max parallel resistance of 3k. As the pot is turned the equivalent resistance decreases.

Now, changing the value of one resistor and adding another onto the back of your pot, you now have a bias control with a fully functional range of sweep(instead of 1/3 of it making sound.

It does take a little bit more thought and planning, but not much more work that bringing it to the front panel.

To reiterate, have someone double check my bridging and leg selection. It's probably backwards

Feral Feline

Well-known member

@jwin615 — And a tip of the hat to you too sir!

The thing about SAG pots is that for some people they want it to sag more as they turn the knob CW,

and to others it makes more sense if the voltage is full at full-CW and make it sag more (reduce voltage) turning the knob CCW.

So, at least for a SAG control, whether-or-not the pot is wired backwards is subjective.

Looks okay to me.

The thing about SAG pots is that for some people they want it to sag more as they turn the knob CW,

and to others it makes more sense if the voltage is full at full-CW and make it sag more (reduce voltage) turning the knob CCW.

So, at least for a SAG control, whether-or-not the pot is wired backwards is subjective.

Looks okay to me.

MobyOctopad

Active member

Bit of a dumb question, but if you wanted to add a sag pot to a Sandspur instead, would you just tack on the pot like Feral Feline laid out, or would the additional control also require changes to other parts of the Sandspur's circuit?Note: when. Towing legs of a pot together to use a a variable resistor, I will do it wrong/backwards 97.36% of the time. So, take this fact into account and test it on a breadboard or get info from someone who can work out left right mentally without physically breaking things.

Ok---

Great write up FF. I'll add in that if you want to bring the bias to the front panel, you may want to find the usable range and wire it accordingly.

Using the Silismile as an example again.

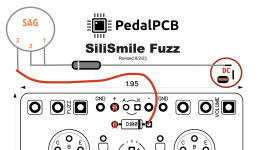

View attachment 78851

Say, the usae range of the bias trimmer is 4k to 7k. Well, you have a 1k resistor in series already so your total bias resistance that has desirable sound is 5k-8k.

Our biggest restriction in doing this is fixed pot value.

You can modify R3 to your minimum usable resistance. Now you'll need to figure out parallel resistances to get 3k in series with R3. There's a formula, or a billion free calculators. Going with a 5k pot, adding a 7.5k resistor in parallel with our 5k pot gives us a net max parallel resistance of 3k. As the pot is turned the equivalent resistance decreases.

View attachment 78852

Now, changing the value of one resistor and adding another onto the back of your pot, you now have a bias control with a fully functional range of sweep(instead of 1/3 of it making sound.

It does take a little bit more thought and planning, but not much more work that bringing it to the front panel.

To reiterate, have someone double check my bridging and leg selection. It's probably backwards

I mean, there always a harder way to do it. But that would work fine.Bit of a dumb question, but if you wanted to add a sag pot to a Sandspur instead, would you just tack on the pot like Feral Feline laid out, or would the additional control also require changes to other parts of the Sandspur's circuit?

Note, on the sandspur the "sundial" control IS a bias control.

Bringing bias to the front panel would be redundant as the two resistances are in series.

I don't think you'll find a ton of use in a sag control with the sundial control trimmed down though. Maybe a few more flavors of fart before it just shuts off.

An external bias trim and a sag control do the same thing. It's just a bias usually only starves one gain stage and a sag starves all gain stages.

Double starving the second gain stage will end in a glorious sound of non-functional.

Feral Feline

Well-known member

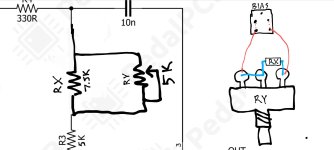

What Jwin615 describes is exactly what's going on in a Fuzz Foundry, both in series and parallel though.

Take a look at the schematic MobyOctopad and Ac30irons:

The SAG (STAB) control feeds both a bias adjustment (COMP) that's in parallel with yet another pot (DRIVE).

That makes for some wildly interactive powering of Q3 (3 pots!) The COMP and DRIVE alone are enough to produce some wacky results since they are in parallel with each other — going back to what Jwin615 was describing putting a resistor across a pot to change its overall resistance:

That's just madness to make that resistor across the pot another variable-resistor. Then to starve it all...

No wonder some people don't get along with the Fuzz Factory circuit.

So while you could add a SAG to the Sandspur, as Jwin615 already pointed out, there'd be diminishing returns to doing so.

Instead of adding a global SAG on the Sandspur, I'd mess with R2 and try something like 25k fixed resistor in series with a 10k pot.

Take a look at the schematic MobyOctopad and Ac30irons:

The SAG (STAB) control feeds both a bias adjustment (COMP) that's in parallel with yet another pot (DRIVE).

That makes for some wildly interactive powering of Q3 (3 pots!) The COMP and DRIVE alone are enough to produce some wacky results since they are in parallel with each other — going back to what Jwin615 was describing putting a resistor across a pot to change its overall resistance:

That's just madness to make that resistor across the pot another variable-resistor. Then to starve it all...

No wonder some people don't get along with the Fuzz Factory circuit.

So while you could add a SAG to the Sandspur, as Jwin615 already pointed out, there'd be diminishing returns to doing so.

Instead of adding a global SAG on the Sandspur, I'd mess with R2 and try something like 25k fixed resistor in series with a 10k pot.

Last edited:

The knowledge you guys have never ceases to amaze meWhat Jwin615 describes is exactly what's going on in a Fuzz Foundry, both in series and parallel though.

Take a look at the schematic MobyOctopad and Ac30irons:

The SAG (STAB) control feeds both a bias adjustment (COMP) that's in parallel with yet another pot (DRIVE).

That makes for some wildly interactive powering of Q3 (3 pots!) The COMP and DRIVE alone are enough to produce some wacky results since they are in parallel with each other — going back to what Jwin615 was describing putting a resistor across a pot to change its overall resistance:

View attachment 78858

That's just madness to make that resistor across the pot another variable-resistor. Then to starve it all...

No wonder some people don't get along with the Fuzz Factory circuit.

So while you could add a SAG to the Sandspur, as Jwin615 already pointed out, there'd be diminishing returns to doing so.

Instead of adding a global SAG on the Sandspur, I'd mess with R2 and try something like 25k fixed resistor in series with a 10k pot.

Feral Feline

Well-known member

Speaking for myself, knowledge accumulated gradually — I have just barely enough now to be dangerous.

I get the "dieing battery" idea, for sure(as a partaker of sonic mayhem myself). But only in a circuit that doesn't have an external bias control. Otherwise it's a frustrating redundancy.I’m still not sure I understand why people want to vary the source voltage.

Is it the desire to have a global bias control?

Big Monk

Well-known member

I get the "dieing battery" idea, for sure(as a partaker of sonic mayhem myself).

Sure, but a “sag” control doesn’t simulate a dying battery.

I think we had this discussion in the forums a couple years ago and a proper battery simulator circuot has more parts than the Fuzz Face does!

But only in a circuit that doesn't have an external bias control. Otherwise it's a frustrating redundancy.

Exactly. It’s basically a a global bias control but I personally don’t want to play with the bias on Q1.

giovanni

Well-known member

The fuzz foundry already has a sag control, but it’s called stab (stability).The Fuzz Foundry is like a Factory-made Fuzz Face; so use that as your template.

Are you building your FF on a PCB, vero, perf, tagboard, PtoP?

I'll use Robert's Foundry and SiliSmile schematics to illustrate:

View attachment 78837

Using the Fuzz Foundry as an example to building SAG into your SiliSmile:

- Lift one end of each D100 and C100, the ends that meet, ie don't solder those ends to the board, just the ends that go to power-input and ground respectively;

- solder the diode and caps loose ends with a wire together,

- other end of wire goes to your pot SAG's lug-1 & jumper lug-1 to lug-2.

- solder a wire from SAG lug-3 back to the remaining pad for D100 (or C100, whichever is more convenient).

- Fire up the board (you've already populated/soldered with all components jacks pots etc) and congratulate yourself on having added a SAG pot.

You could also omit C100 from the board entirely and solder one end of it to lug 1 or 2 of SAG and the other end to ground.

For that matter you could run D100 direct from the DC jack to the SAG lug-1 (or lug-2, since 1&2 lugs are jumpered), and not bother populating

D100 nor C100 on the board at all...

OR

As described above, but instead of D100 & C100, lifting the ends of R2 & R4 of the SiliSmile (see the build doc for full schematic).

You'll need to set your DMM to Batfink-Beep mode to determine which is the correct end of the components you want to lift. (I don't have the PCB to check myself)

View attachment 78839

Looking at the diagram above, I'd personally choose running D100 straight from the power-jack to the SAG pot lug-1&2 and a wire from lug-3 to the square pad of D100. ( and C100 can stay where it is ).

Yeah, there's a million ways to skin a cat, but often the simplest is best.

Leave D100 off the board and run it from the DC jack to the SAG pot and the output of the SAG to the board's D100 square-pad (make sure you've oriented the diode correctly ie stripey-end connects to the pot).

View attachment 78840

Similar threads

- Replies

- 27

- Views

- 1K