This is my project thread to invite comments / mockery *cough* shared laughter or any input readers might deem worth while

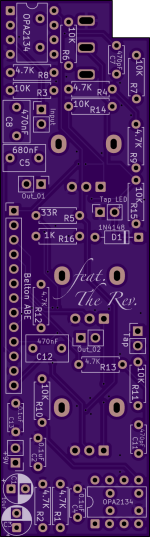

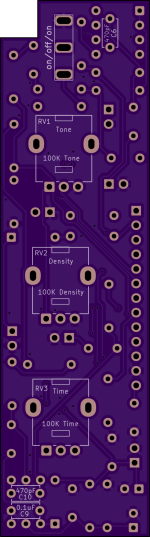

Here is my draft graphic of the Effector against the Reverb

I have yet to label the three way switch at top left. It will be up-Reverb, mid-Delay, down-Chorus.

The labelled switch second top left, is the voicing switch similar to the Mod I built from TassiVicking's idea.

There will also be another momentary footswitch in the bottom left corner for the tap-tempo.

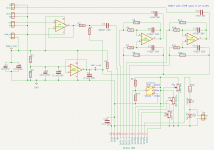

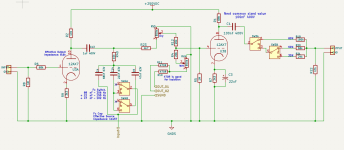

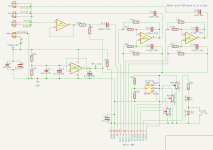

I have based the circuit from the ABE data-sheet example and borrowed ideas from the GT-Stasis Lead Build. Schematic attached.

Thoughts? Ideas for a better name?

Here is my draft graphic of the Effector against the Reverb

I have yet to label the three way switch at top left. It will be up-Reverb, mid-Delay, down-Chorus.

The labelled switch second top left, is the voicing switch similar to the Mod I built from TassiVicking's idea.

There will also be another momentary footswitch in the bottom left corner for the tap-tempo.

I have based the circuit from the ABE data-sheet example and borrowed ideas from the GT-Stasis Lead Build. Schematic attached.

Thoughts? Ideas for a better name?