MichaelW

Well-known member

- Build Rating

- 5.00 star(s)

Ok, when I typed in "biggus" in the title I got a lot of responses of a more vulgar "Biggus" pedals hahaha.

This is @MattG's Gigantic Sauce Container PCB that he was so kind to send me. Based on the Way Huge Saucy overdrive that I had never heard of.

It's very rare for me to build an overdrive that impresses me so much that it goes right into my signal chain as a resident.

Thats what happened after I built this one. Man, I LOVE this pedal. It's right up my alley.

The drive is kind of a loosey goosey lo fi-ish medium gain drive. It sounds great with both my Strat and Les Paul.

There's a touch of Klon to it but it's not the main feature. It has a mix knob that blends the clean signal in (I think), which makes it somewhat Klon-ish.

But the gain voicing is really very cool sounding and not the usual hard/soft clipping fare.

I haven't looked at the schematic so I don't know if it's based on anything else but it's just a great sounding overdrive.

This is Matt's first stacked board and I think he knocked it out of the park. The second board has his electrical switching schema and it's pretty sweet!

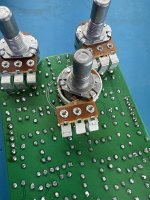

So when I first put it together, I noticed the tone knob was kind of "crunchy" to turn, like I could feel the wafers. But I decided to box it up and try it anyway.

The tone knob didn't work. Sigh, so I had to take the beast apart to take a look and this is what I found, first time I've ever seen this.....like WTF?

Anyway, I popped a new pot and voila, it works perfect,

I know in Matts report he had some issues with making sure he had low profile caps and the DIP strip socketing he used to connect the boards.

I've done a number of stacked boards and I've always just used standard molex type connectors and they were the perfect height.

(Very much like @Robert 's and @dan.schumaker 's stacked boards.

The only issue I had was the 470uf power filter cap. The BOM called for a 220uf but Matt said going higher would be better so I went with a 470u.

It was "just" right to get the back cover on.

Aside from those two sphincter clenching moments, everything else about the build went perfectly.

What a great sounding overdrive! Thanks again so much @MattG !

This is @MattG's Gigantic Sauce Container PCB that he was so kind to send me. Based on the Way Huge Saucy overdrive that I had never heard of.

It's very rare for me to build an overdrive that impresses me so much that it goes right into my signal chain as a resident.

Thats what happened after I built this one. Man, I LOVE this pedal. It's right up my alley.

The drive is kind of a loosey goosey lo fi-ish medium gain drive. It sounds great with both my Strat and Les Paul.

There's a touch of Klon to it but it's not the main feature. It has a mix knob that blends the clean signal in (I think), which makes it somewhat Klon-ish.

But the gain voicing is really very cool sounding and not the usual hard/soft clipping fare.

I haven't looked at the schematic so I don't know if it's based on anything else but it's just a great sounding overdrive.

This is Matt's first stacked board and I think he knocked it out of the park. The second board has his electrical switching schema and it's pretty sweet!

So when I first put it together, I noticed the tone knob was kind of "crunchy" to turn, like I could feel the wafers. But I decided to box it up and try it anyway.

The tone knob didn't work. Sigh, so I had to take the beast apart to take a look and this is what I found, first time I've ever seen this.....like WTF?

Anyway, I popped a new pot and voila, it works perfect,

I know in Matts report he had some issues with making sure he had low profile caps and the DIP strip socketing he used to connect the boards.

I've done a number of stacked boards and I've always just used standard molex type connectors and they were the perfect height.

(Very much like @Robert 's and @dan.schumaker 's stacked boards.

The only issue I had was the 470uf power filter cap. The BOM called for a 220uf but Matt said going higher would be better so I went with a 470u.

It was "just" right to get the back cover on.

Aside from those two sphincter clenching moments, everything else about the build went perfectly.

What a great sounding overdrive! Thanks again so much @MattG !