You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Looks like I'm out of excuses...

- Thread starter peccary

- Start date

Well we all know what amps sound like with tolex! What I found when I made the cabinets identically with or without tolex out of solid pine was the without tolex had a kind of extra presence. There is a high frequency which must be dampened by the glue and tolex - it's a kind of sibilance or something. It's subtle but definitely noticeable - at least it is to me because for some inexplicable reason I haven't completely lost my high frequency hearing. It's not better but I quite like it. Tolex seems to roll off the extreme high frequencies and make things smoother. It's difficult to explain but it's a very high frequency where the sound is happening.

It's a bit like someone whispering in your ear - you hear the extra high frequency detail.

It's a bit like someone whispering in your ear - you hear the extra high frequency detail.

temol

Well-known member

Contact me via PM if you need some tips regarding enclosure designI imagine it will take some planning and trial and (lots of) error, but now it looks like I now have a new direction to try out in terms of making my own enclosures.

peccary

Well-known member

I'm always up for tips, I may have to take you up on that.Contact me via PM if you need some tips regarding enclosure design

I have to get my hands on something before I can get an idea of what I'm going to do, really. Today I roughed out a shape I thought I liked out of cardboard and then eyeballed it in the bender with some 22 ga sheet I picked up. Just working on a bit of a prototype and have learned a lot already.

The first ting I learned was that I should have paid better attention in geometry class

Really, though: even though the dimensions are off I feel pretty good about this. I more or less eyeballed the angles but I got my hands on the bender which is what was important in getting my eye in and feeling out how it works. I messed up the second bend and over-bent it, so I had to bang out the first bend to fix the second one, which is why that bottom edge (and subsequently that whole side) got wavy.

I need a better handle on angles, for sure. It needs to be shorter overall and a bit flatter, but like I said - I really just needed to do it once to know what I needed to know. My cousin recommended trying to learn some basic CAD and recommended Tinkercad. If I can't get a handle on that I think I'll just go with graph paper and protractor.

All in all it was a good experiment and I learned a lot. I also managed to work out all of the grease they coated the bender in. I'm going to smell like a mechanic for a week.

Passinwind

Well-known member

If you end up needing to use an online vendor these guys have been great to deal with for what I needed: https://www.onlinemetals.comSupposedly it can do up 20 ga mild steel and 16 ga aluminum.

There's a metal supply place not far from me and I may swing by this weekend to see what they have in stock. Hopefully I can find something that needs minimal cutting as that's another concern. I have shears but cleaning that all up will be time consuming.

My application was specialized bass slides and their selection of bar stock was pretty sick. No problem having them cut a few different types to my specs. They do water jet cutting now too, which might work out well for your needs?

Feral Feline

Well-known member

I was just looking at some mini-brakes that mount in a bench vise a few days ago, and then ...

... I see this thread.

I am jelly yes, but ssssooo excited for you!

The Enigmatic Peccary — Phantom of the Double-Bass, Surreptitious-Cyclist, Secret-Smithy ... a man of many undisclosed talents. What other mysteries of himself will he reveal in time?

... I see this thread.

I am jelly yes, but ssssooo excited for you!

The Enigmatic Peccary — Phantom of the Double-Bass, Surreptitious-Cyclist, Secret-Smithy ... a man of many undisclosed talents. What other mysteries of himself will he reveal in time?

peccary

Well-known member

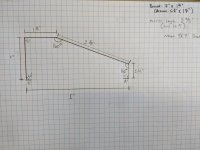

I mentioned earlier that my cousin (he's a machinist and has about 25 years experience, which is why I cite him as my authority on a lot of this stuff) recommended a basic CAD program online. I spent a couple of hours with it and gained more frustration than knowledge, so I decided to break out the compass and pencil.

Two plus hours fiddling with a computer program or 20 minutes of drawing and measuring. I'll take it.

I like these proportions much better than the first, and drawing it in this way allowed me to find all of the angles as well as the overall length of the material I'll need. Next I'm going to put it on some card stock and tape it up to be sure I can fit everything, and I want to see it in three dimensions. After that I'm going to have to source some sheet that will meet my specs, so thank you @Passinwind for the link above - that site is very helpful. And after speaking with @temol I have a much better idea of what kind of material I need to look at and how to layout the switch.

Just a quick update as to where I'm at and props to some awesome folks who have helped me out. I'm looking forward to this moving along. Things have gotten a little busier these past couple of weeks so I have slowed down, but putting in a little bit of time when I have it has been keeping me going.

Two plus hours fiddling with a computer program or 20 minutes of drawing and measuring. I'll take it.

I like these proportions much better than the first, and drawing it in this way allowed me to find all of the angles as well as the overall length of the material I'll need. Next I'm going to put it on some card stock and tape it up to be sure I can fit everything, and I want to see it in three dimensions. After that I'm going to have to source some sheet that will meet my specs, so thank you @Passinwind for the link above - that site is very helpful. And after speaking with @temol I have a much better idea of what kind of material I need to look at and how to layout the switch.

Just a quick update as to where I'm at and props to some awesome folks who have helped me out. I'm looking forward to this moving along. Things have gotten a little busier these past couple of weeks so I have slowed down, but putting in a little bit of time when I have it has been keeping me going.

Bricksnbeatles

Member known well

I’ve done a bit of work with tinkercad if you need pointers. I’m not too proficient, but I’ve got a decent handle on itI mentioned earlier that my cousin (he's a machinist and has about 25 years experience, which is why I cite him as my authority on a lot of this stuff) recommended a basic CAD program online. I spent a couple of hours with it and gained more frustration than knowledge, so I decided to break out the compass and pencil.

Two plus hours fiddling with a computer program or 20 minutes of drawing and measuring. I'll take it.

I like these proportions much better than the first, and drawing it in this way allowed me to find all of the angles as well as the overall length of the material I'll need. Next I'm going to put it on some card stock and tape it up to be sure I can fit everything, and I want to see it in three dimensions. After that I'm going to have to source some sheet that will meet my specs, so thank you @Passinwind for the link above - that site is very helpful. And after speaking with @temol I have a much better idea of what kind of material I need to look at and how to layout the switch.

Just a quick update as to where I'm at and props to some awesome folks who have helped me out. I'm looking forward to this moving along. Things have gotten a little busier these past couple of weeks so I have slowed down, but putting in a little bit of time when I have it has been keeping me going.

View attachment 27446

swyse

Well-known member

I'm a bit late to the party, but I found onshape to be fairly intuitive for someone who has no CAD experience whatsoever. I made something similar to this, but never did anything with it.

https://cad.onshape.com/documents/b...5d6c562d803a08655f/e/314c202bd6408808c8120055

On the right you can view it as a flat piece of metal with the cuts and bends. I don't remember the exact details of the design, this was just something I was thinking about for doing a one knob fuzz.

https://cad.onshape.com/documents/b...5d6c562d803a08655f/e/314c202bd6408808c8120055

On the right you can view it as a flat piece of metal with the cuts and bends. I don't remember the exact details of the design, this was just something I was thinking about for doing a one knob fuzz.