temol

Well-known member

Calling Eagle freaks...

I'm trying to design a fooprint for a slim audio jack. I'd like to use oblong holes/slots instead of ordinary big holes but Eagle does not support oblong holes.

I've seen couple of solutions but I couldn't find a clear answer - which method is proven and working.

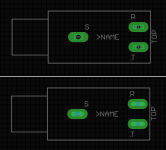

As for now I have two versions of the same footprint, both using milling layer for a slot shape. Version on the top - rectangle inside a solderpad . Bottom version - single line with appriopriate width (width of the slot).

Any tips?

I'm trying to design a fooprint for a slim audio jack. I'd like to use oblong holes/slots instead of ordinary big holes but Eagle does not support oblong holes.

I've seen couple of solutions but I couldn't find a clear answer - which method is proven and working.

As for now I have two versions of the same footprint, both using milling layer for a slot shape. Version on the top - rectangle inside a solderpad . Bottom version - single line with appriopriate width (width of the slot).

Any tips?