Danbieranowski

Well-known member

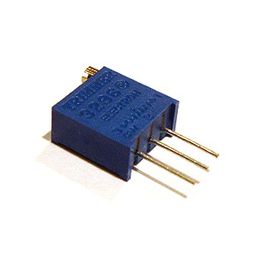

I like to do this from time to time if I'm doing a combo build and I want to hide some of the controls internally. Has anyone come up with a clever way of fitting the trimmer to the spaced 16mm PCB mount pot holes that isn't just putting a wire out to the 3 legs? I'm looking for something a little more professional or secure looking than that if anyone is aware of an adapter board or anything.