BuddytheReow

Moderator

A few people have asked me about stripboard so I thought I'd do a simple writeup. Turned out a lot longer to make it "simple", but I covered the bases here.

What is Stripboard?

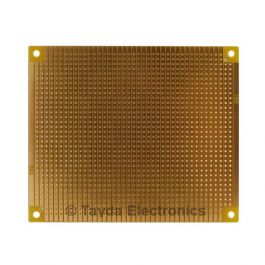

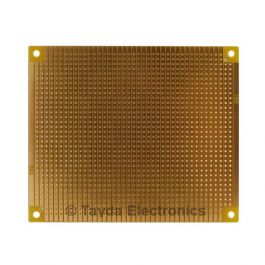

Stripboard is simply a different type of prototyping platform. If soldering is your main vice, this is the way to go and is considered to be a more permanent way to keep a circuit instead of breadboarding. I say more permanent because you can always desolder and save your components if you really want for a different build. This is what stripboard looks like and there are different size boards available. This is just the back side.

You can see there are multiple rows here. These are simply just individual strips of copper with holes spaced evenly throughout. These strips are separated by a small track in between them.

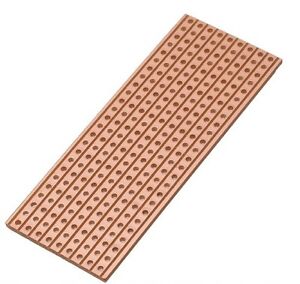

This is the front side of the board. I just grabbed something from my stash to show you guys what it looks like. It has obviously been cut at the top, but this piece is perfectly useable for a new project. The top of the board does not conduct current in any way. This is the side your components go in.

If this is Stripboard, then what's Veroboard?

Like Styrofoam, Veroboard was the original branded name. Stripboard and Veroboard are the same thing.

In my google searches I see 'Prototyping Board'. What's that?

Be careful here when shopping. There are other types of boards out there with different layouts of copper strips other than the single rows. Some boards don't have any copper strips, just a little bit of copper around the holes. This is perfboard territory and can be a separate writeup if needed. This is not what you want if you're just curious about stripboard.

When you are shopping for stripboard make sure you can see the underside of the board in the pictures to make sure you are getting stripboard and not perf or something else with a wacky layout. You want the long tracks. This is what I use and get it from Tayda. These are really cheap (in a good way) ($1.29) and I've had no problems with them.

www.taydaelectronics.com

www.taydaelectronics.com

Stripboard vs a PCB

Stripboard has it's advantages and disadvantages.

Advantages:

-It's cheap. I can get a large board from Tayda for $1.29. One board can be used for multiple projects and really depends on the size of the layouts needed.

-You can build multiple projects from a single, large board. If you really wanted to you make one project per board. Runoffgroove site does that a lot and there's nothing wrong with that.

-This is not a reflection on PedalPCB in any way, but there are more stripboard layouts online than there are PCBs here on this site. I guess PedalPCB has some catchup work to do.

-Because it's cheap, if you're really not happy with the circuit or the circuit doesn't work as laid out you can desolder everything and throw away the board.

-Like breadboarding, there are multiple ways to make a circuit. You will find multiple layouts for the same circuit in your google searches. This is also a disadvantage and I'll explain below.

-IMO this is easier to solder components than on a PCB. You don't have to hold the iron to the board as long (just a second or two).

-It's true DIY. You are building the board from scratch. It's a great feeling knowing you built something all on your own!

Disadvantages:

-The main disadvantage, IMO, is the offboard wiring. It looks a mess depending on how many knobs you have and the way the layout is designed.

-Trying to design a circuit on stripboard can be quite confusing. The layouts do not flow like a schematic (read left to right normally) and it's a different way of thinking like breadboarding. Tagboard has a good write up how to do it. You will definitely need to know how to read a schematic. http://tagboardeffects.blogspot.com/2012/09/vero-layout-guide.html

-Like schematics found on the web, they may be incorrect in terms of component values or the circuit just won't work as laid out. To counter this, when I'm looking for a new circuit to build I always try to see if others have built it. The main sites I get them from usually have a tag as 'Verified". If you really want to be adventurous you can try an unverified one and see if it works.

-Troubleshooting can be a real pain the ass for these since they don't flow the same way as a schematic. If the usual suspects don't appear (bad components or solderinng) it will be a pain trying to probe the circuit

OK. I want to build a circuit. Where can I find them?

There are many resources out there, but these are the main ones that I stick to. These are tried, true, and honest sites, but there are others out there. Between these 2 sites there are over 1,000 layouts that work and are supposedly verified from someone. I would also read the comments for these layouts to see what worked and didn't work for others whether they chose to experiment or not.

tagboardeffects.blogspot.com

tagboardeffects.blogspot.com

dirtboxlayouts.blogspot.com

dirtboxlayouts.blogspot.com

What's the process to build one?

The soldering part is a no-brainer, but I'll try to keep this as concise as possible. First you'll need to find a layout. I chose this one since it's pretty simple and sums up the main process and most of the quirks with stripboard.

Let's look at the right side first. Stripboard layouts are usually done this way with the strips going horizontally. "10 x 8" simply means there are 10 holes across and 8 strips down. This board has 1 link and 2 cuts, meaning that 2 of the strips are jumpered together and is shown exactly where with that black line. You can use hookup wire, ends of resistor leads, or anything else that conducts. I've noticed that if the spacing is 7 or more rows apart I need to use hookup wire since the leads don't get that long. It's really personal preference.

"Cuts" simply mean you are severing the conductivity of that strip at that specific point. Keep in mind this is viewed from the top of the board and not the bottom. What I do, and this is my personal preference, is take a sharpie and mark the holes on the top side. I flip the board over on top of a white piece of paper and I can see where I made my marks. I then take a drill bit that's just wider that the strip and twirl it with my fingers to remove the copper.

Cutting the board to size

If YouTube is your resource here's a good tutorial. I'll also mention it here.

This layout is 10 x 8. You will need to cut the board on the 11th hole and 9th row in the middle of the holes. To cut the board, simply take a straight edge and score it along the middle of the holes. I use a utility knife and it works fine, but you can use anything that will scratch the board such as a screwdriver head. After a few scores you can snap it off by hand or use a pair of pliers to make sure it snaps along the scored line.

Now the left side of the layout

This side of the board tells you exactly where to put your components and what values they are. Note that the leads are all different lengths and act as jumpers between rows in addition to doing what the component is supposed to do in the circuit. It will also tell you the orientation of the components as well such as the transistor pinouts and electrolytic caps. I would highly recommend sockets for transistors and ICs for either experimenting or to easily remove them if you don't like the circuit. The - side of the cap is shown by that light blue strip underneath the "10u" in the layout above. The transistors and ICs are usually labelled (numbered) around the board and the suggested component or pot value to use is mentioned in the legend on the bottom left. Most ICs are oriented with pin 1 in the top left corner and if not it will be said in the layout itself or in the writeup of these layouts. Another reason why sockets are important here. It's not in this layout, but diodes are marked with a white or offcolored line to indicate the cathode (-) side.

Offboard wiring

This is stripboard's main downfall here. Most layouts you find online have color-coordinated wiring of some kind and the wires are almost always labelled. The wires are usually installed right at the edges of the board. Note that in this particular layout, the output signal is coming out of lug 2 of the volume pot and not directly from the board. Depending on the layout you choose you may have a spider web of wires going between pot lugs. Some layouts don't even have a pot connected to the board but rather to other pots! If you're a perfectionist and love some robot porn you will be disappointed in how it looks. IMO it's more important to have the circuit work with as little noise as possible since you won't see the wiring when you choose to box it all up.

You've just finished soldering. Some tips.

Once you've completed all your soldering it's good practice to take your iron and run it along the individual track of the underside of the board. This is to remove any accidental solder bridges and flux that may have spilled over. It's also a good idea to double check your soldering skills here and reflow as necessary.

Get a test box of some kind. You can use a breadboard/protoboard, the auditorium test platform or make your own test box. I like the test box since it's another excuse to DIY something. Here's a good idea from tagboard to make one. I also built one based on this. http://tagboardeffects.blogspot.com/2014/09/test-box-20.html.

What is Stripboard?

Stripboard is simply a different type of prototyping platform. If soldering is your main vice, this is the way to go and is considered to be a more permanent way to keep a circuit instead of breadboarding. I say more permanent because you can always desolder and save your components if you really want for a different build. This is what stripboard looks like and there are different size boards available. This is just the back side.

You can see there are multiple rows here. These are simply just individual strips of copper with holes spaced evenly throughout. These strips are separated by a small track in between them.

This is the front side of the board. I just grabbed something from my stash to show you guys what it looks like. It has obviously been cut at the top, but this piece is perfectly useable for a new project. The top of the board does not conduct current in any way. This is the side your components go in.

If this is Stripboard, then what's Veroboard?

Like Styrofoam, Veroboard was the original branded name. Stripboard and Veroboard are the same thing.

In my google searches I see 'Prototyping Board'. What's that?

Be careful here when shopping. There are other types of boards out there with different layouts of copper strips other than the single rows. Some boards don't have any copper strips, just a little bit of copper around the holes. This is perfboard territory and can be a separate writeup if needed. This is not what you want if you're just curious about stripboard.

When you are shopping for stripboard make sure you can see the underside of the board in the pictures to make sure you are getting stripboard and not perf or something else with a wacky layout. You want the long tracks. This is what I use and get it from Tayda. These are really cheap (in a good way) ($1.29) and I've had no problems with them.

Big StripBoard 110x93mm (Copper)

High Quality - Get It Fast - Same Day Shipping

Stripboard vs a PCB

Stripboard has it's advantages and disadvantages.

Advantages:

-It's cheap. I can get a large board from Tayda for $1.29. One board can be used for multiple projects and really depends on the size of the layouts needed.

-You can build multiple projects from a single, large board. If you really wanted to you make one project per board. Runoffgroove site does that a lot and there's nothing wrong with that.

-This is not a reflection on PedalPCB in any way, but there are more stripboard layouts online than there are PCBs here on this site. I guess PedalPCB has some catchup work to do.

-Because it's cheap, if you're really not happy with the circuit or the circuit doesn't work as laid out you can desolder everything and throw away the board.

-Like breadboarding, there are multiple ways to make a circuit. You will find multiple layouts for the same circuit in your google searches. This is also a disadvantage and I'll explain below.

-IMO this is easier to solder components than on a PCB. You don't have to hold the iron to the board as long (just a second or two).

-It's true DIY. You are building the board from scratch. It's a great feeling knowing you built something all on your own!

Disadvantages:

-The main disadvantage, IMO, is the offboard wiring. It looks a mess depending on how many knobs you have and the way the layout is designed.

-Trying to design a circuit on stripboard can be quite confusing. The layouts do not flow like a schematic (read left to right normally) and it's a different way of thinking like breadboarding. Tagboard has a good write up how to do it. You will definitely need to know how to read a schematic. http://tagboardeffects.blogspot.com/2012/09/vero-layout-guide.html

-Like schematics found on the web, they may be incorrect in terms of component values or the circuit just won't work as laid out. To counter this, when I'm looking for a new circuit to build I always try to see if others have built it. The main sites I get them from usually have a tag as 'Verified". If you really want to be adventurous you can try an unverified one and see if it works.

-Troubleshooting can be a real pain the ass for these since they don't flow the same way as a schematic. If the usual suspects don't appear (bad components or solderinng) it will be a pain trying to probe the circuit

OK. I want to build a circuit. Where can I find them?

There are many resources out there, but these are the main ones that I stick to. These are tried, true, and honest sites, but there are others out there. Between these 2 sites there are over 1,000 layouts that work and are supposedly verified from someone. I would also read the comments for these layouts to see what worked and didn't work for others whether they chose to experiment or not.

Guitar FX Layouts

Collection of vero (stripboard) & tagboard layouts for 100s of popular guitar effects, with over 1000 verified designs. DIY your own boutique effects!

Dirtbox Layouts

What's the process to build one?

The soldering part is a no-brainer, but I'll try to keep this as concise as possible. First you'll need to find a layout. I chose this one since it's pretty simple and sums up the main process and most of the quirks with stripboard.

Let's look at the right side first. Stripboard layouts are usually done this way with the strips going horizontally. "10 x 8" simply means there are 10 holes across and 8 strips down. This board has 1 link and 2 cuts, meaning that 2 of the strips are jumpered together and is shown exactly where with that black line. You can use hookup wire, ends of resistor leads, or anything else that conducts. I've noticed that if the spacing is 7 or more rows apart I need to use hookup wire since the leads don't get that long. It's really personal preference.

"Cuts" simply mean you are severing the conductivity of that strip at that specific point. Keep in mind this is viewed from the top of the board and not the bottom. What I do, and this is my personal preference, is take a sharpie and mark the holes on the top side. I flip the board over on top of a white piece of paper and I can see where I made my marks. I then take a drill bit that's just wider that the strip and twirl it with my fingers to remove the copper.

Cutting the board to size

If YouTube is your resource here's a good tutorial. I'll also mention it here.

This layout is 10 x 8. You will need to cut the board on the 11th hole and 9th row in the middle of the holes. To cut the board, simply take a straight edge and score it along the middle of the holes. I use a utility knife and it works fine, but you can use anything that will scratch the board such as a screwdriver head. After a few scores you can snap it off by hand or use a pair of pliers to make sure it snaps along the scored line.

Now the left side of the layout

This side of the board tells you exactly where to put your components and what values they are. Note that the leads are all different lengths and act as jumpers between rows in addition to doing what the component is supposed to do in the circuit. It will also tell you the orientation of the components as well such as the transistor pinouts and electrolytic caps. I would highly recommend sockets for transistors and ICs for either experimenting or to easily remove them if you don't like the circuit. The - side of the cap is shown by that light blue strip underneath the "10u" in the layout above. The transistors and ICs are usually labelled (numbered) around the board and the suggested component or pot value to use is mentioned in the legend on the bottom left. Most ICs are oriented with pin 1 in the top left corner and if not it will be said in the layout itself or in the writeup of these layouts. Another reason why sockets are important here. It's not in this layout, but diodes are marked with a white or offcolored line to indicate the cathode (-) side.

Offboard wiring

This is stripboard's main downfall here. Most layouts you find online have color-coordinated wiring of some kind and the wires are almost always labelled. The wires are usually installed right at the edges of the board. Note that in this particular layout, the output signal is coming out of lug 2 of the volume pot and not directly from the board. Depending on the layout you choose you may have a spider web of wires going between pot lugs. Some layouts don't even have a pot connected to the board but rather to other pots! If you're a perfectionist and love some robot porn you will be disappointed in how it looks. IMO it's more important to have the circuit work with as little noise as possible since you won't see the wiring when you choose to box it all up.

You've just finished soldering. Some tips.

Once you've completed all your soldering it's good practice to take your iron and run it along the individual track of the underside of the board. This is to remove any accidental solder bridges and flux that may have spilled over. It's also a good idea to double check your soldering skills here and reflow as necessary.

Get a test box of some kind. You can use a breadboard/protoboard, the auditorium test platform or make your own test box. I like the test box since it's another excuse to DIY something. Here's a good idea from tagboard to make one. I also built one based on this. http://tagboardeffects.blogspot.com/2014/09/test-box-20.html.