leadfoot

Well-known member

After seeing the DOD Grindhaus Fuzz show up in the wish list section and reading up on it and figured I'd make a version of it.

I based it off of the Hype Fuzz from FuzzDog, tossed in the Big Muff tone stack (with the ability to bypass), and then the make up boost as seen in the DOD Grindhaus documentation.

I've attached the schematic circuit and the pcb routing and would like feedback on how to make it better. I'll be using a ground pour on front and back to handle the grounds. When it is all done, I'm using the mad bean suggested trace sizes for power and signal.

I'll be happy to share the gerbers so others can make it as well.

Thanks!

Schematic:

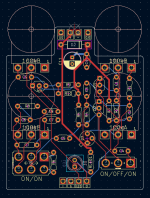

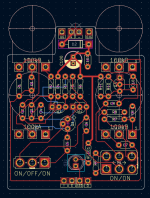

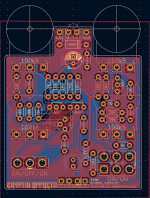

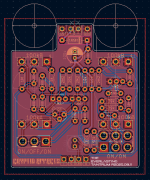

PCB:

I based it off of the Hype Fuzz from FuzzDog, tossed in the Big Muff tone stack (with the ability to bypass), and then the make up boost as seen in the DOD Grindhaus documentation.

I've attached the schematic circuit and the pcb routing and would like feedback on how to make it better. I'll be using a ground pour on front and back to handle the grounds. When it is all done, I'm using the mad bean suggested trace sizes for power and signal.

I'll be happy to share the gerbers so others can make it as well.

Thanks!

Schematic:

PCB: