boji

Active member

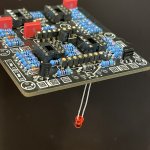

I always struggle with fitting the LED.

Since the LED must be inserted from inside the enclosure, the drilling has to be absolutely spot-on in order for the LED legs to go through the PCB easily. Needless to say, mine is not JoviBenKenobi good yet.

In Jovi’s step-by-step guide, the LED fits right away. It’s almost never the case for me.

Do you have some tips on dealing with the Led? Thanks!

Since the LED must be inserted from inside the enclosure, the drilling has to be absolutely spot-on in order for the LED legs to go through the PCB easily. Needless to say, mine is not JoviBenKenobi good yet.

In Jovi’s step-by-step guide, the LED fits right away. It’s almost never the case for me.

Do you have some tips on dealing with the Led? Thanks!