You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

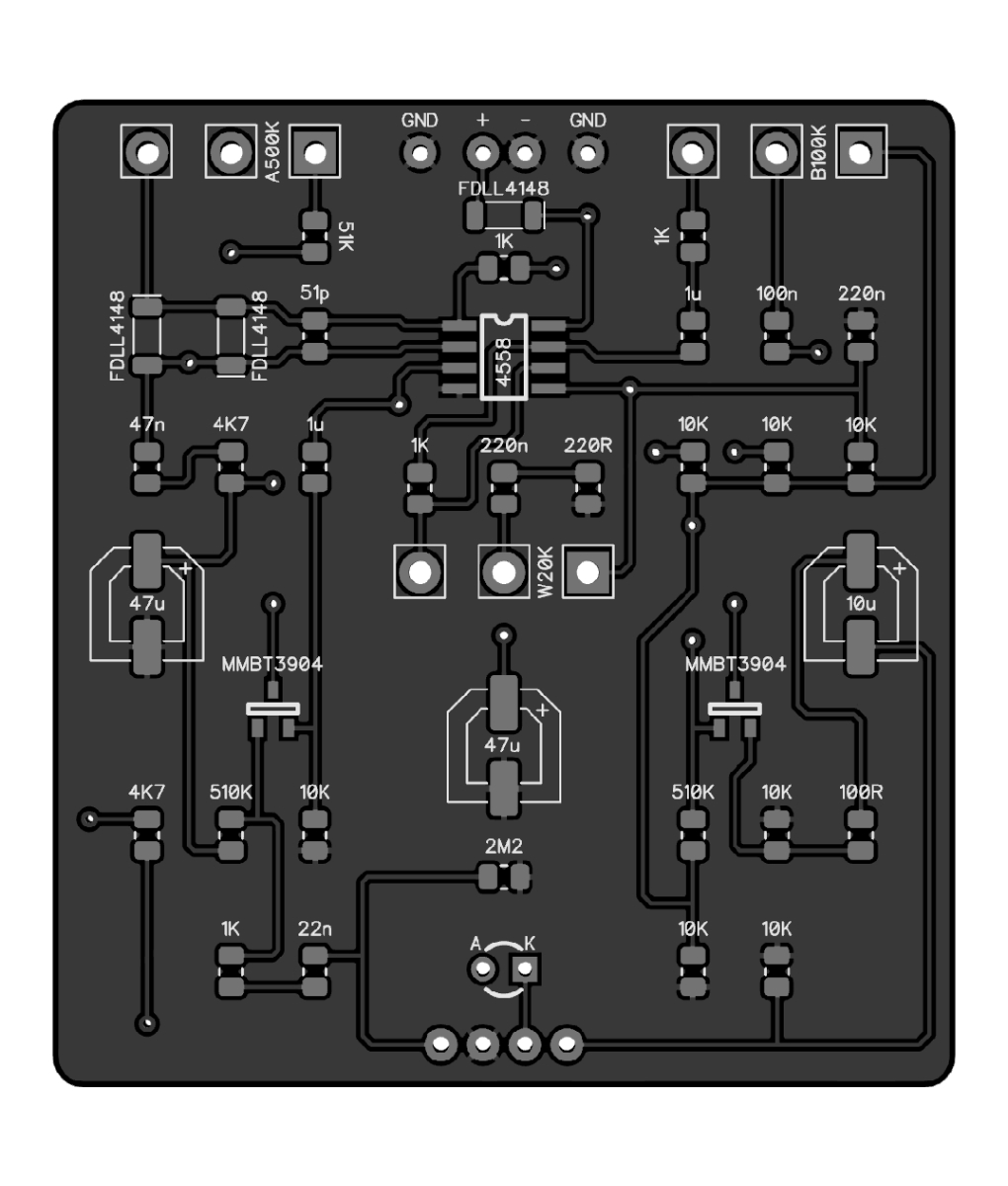

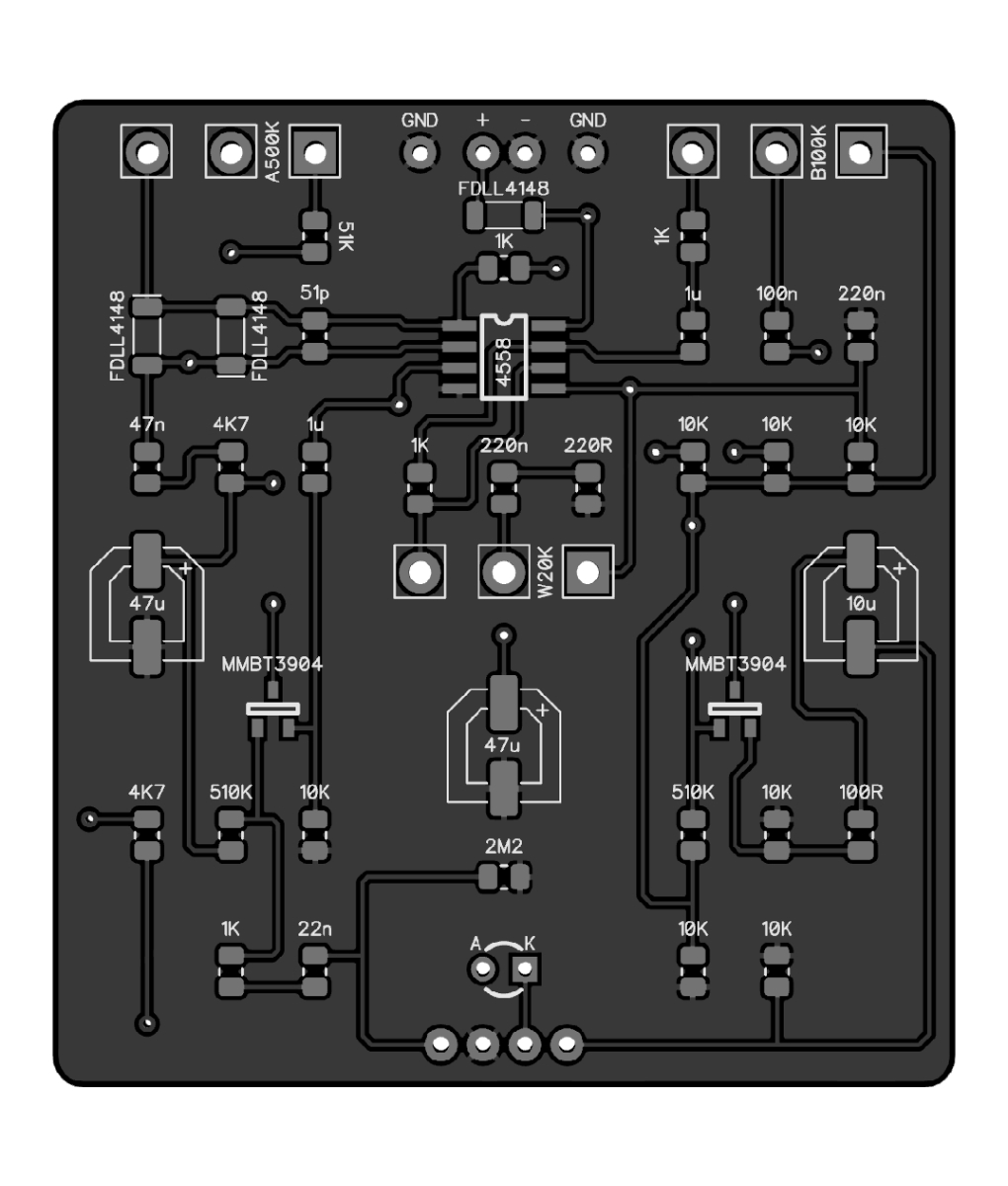

Who's down for some SMD layouts?

- Thread starter Robert

- Start date

Rpschultz13

Well-known member

Last edited:

Rpschultz13

Well-known member

zeropluszero

Well-known member

Hell yeh

Robert

Reverse Engineer

I use 0805 as much as possible for any hand-soldered components.

vigilante398

Authorized Vendor

My personal opinion:

- 1206 or larger - piece of cake, almost as easy as through-hole

- 0805 - easy enough to work with, smallest thing I'll solder without magnification

- 0603 - can hand solder with magnification

- 0402 - will not hand solder, but can do with paste+reflow

- 0201 or 10005 - absolutely freaking not, get that away from me

Rpschultz13

Well-known member

@Robert is your frequency generator based on 0805?I use 0805 as much as possible for any hand-soldered components.

So I should get the 0805 amazon kit instead of the 1206?

Feral Feline

Well-known member

I’d be down for some S&M SMD projects…

vigilante398

Authorized Vendor

Again my personal opinion, it's WAY easier to get it populated by the board house, and they will most likely do a better job than you can by yourself.I ended up looking at SMD stuff for something I'm thinking of laying out... is it easier/satisfying to do by hand vs getting it populated by the pub fabricators?

I realise this is a little off topic!

That being said, for low quantities I find it satisfying to use a solder paste stencil and squeegee the paste on, then place the components and reflow the boards. If you're just doing a handful of boards this can honestly be fun, but if you're doing hundreds of boards it gets real old real fast.

Hand soldering the components on one at a time can be fine if you enjoy hand soldering in general, but it's certainly not fast or easy.

EDIT: Just realized I forgot to mention, board houses will want extra information when assembling boards, likes a BOM and a centroid file, and the level of detail in the BOM and formatting of the centroid are going to depend on the manufacturer. There's an extra bit of time that goes into setting that up, but once you get the hang of it, it's not much extra work on your end.

Last edited:

karter3000

New member

For myself, my limit as far as hand soldering is 0603s (with magnification), mainly due to my eyesight. For my own layouts using SMD, I tend to favor 0603s as I can build them myself, plus I always try to get the board as small as possible.

As far as my work, we go down to 0201s via PnP. If I'm doing a mod for testing or development, I can hand solder 0402s...but it's not comfortable.

As far as my work, we go down to 0201s via PnP. If I'm doing a mod for testing or development, I can hand solder 0402s...but it's not comfortable.

Not to gloat, I’m 36 and my eyesight is alright so long as I have my glasses. My 40+ friends warn me that the readers are coming.

Personally I prefer SMD at this point. I just don’t have to snip leads, make sure components are flush (flipping the board up and down so many times), and components are generally cheaper. I just lay down a puddle of flux and tack components on, spray down with alcohol afterwards, and I’m good to go.

Yes, I’d very much like SMD designs.

Personally I prefer SMD at this point. I just don’t have to snip leads, make sure components are flush (flipping the board up and down so many times), and components are generally cheaper. I just lay down a puddle of flux and tack components on, spray down with alcohol afterwards, and I’m good to go.

Yes, I’d very much like SMD designs.

KreoPensas

Well-known member

Polyimide tape is your very best friend

One more vote for SMD designs. Will gladly let the smoke out of parts.

One more vote for SMD designs. Will gladly let the smoke out of parts.

Feral Feline

Well-known member

Not to jinx things, but PLEASE OH PLEASE OH PLEASE if/WHEN YOU OFFER AN SMD PROJECT, @Robert, PRETTY PLEASE WITH cinnamon & BROWN-SUGAR ON TOP LET IT NOT BE A yats.

Seems any of the other PCB vendors that offer a full-SMD project for the first time it's always a yats.

Muff okay

FuzzFace okay

Bluesbreaker okay

BazzFuss okay

Boost okay

Kemper okay

Dist+/250 okay

chorus okay

flanger GREAT

Guv'nor mm okay

delay okay

KoT okay

EQ okay

Electra okay

MIAB okay

SuperFuzz okay

Rat oh okay

DS-1 o... no.

Seems any of the other PCB vendors that offer a full-SMD project for the first time it's always a yats.

Muff okay

FuzzFace okay

Bluesbreaker okay

BazzFuss okay

Boost okay

Kemper okay

Dist+/250 okay

chorus okay

flanger GREAT

Guv'nor mm okay

delay okay

KoT okay

EQ okay

Electra okay

MIAB okay

SuperFuzz okay

Rat oh okay

DS-1 o... no.

Robert

Reverse Engineer

Not to jinx things, but PLEASE OH PLEASE OH PLEASE if/WHEN YOU OFFER AN SMD PROJECT, @Robert, PRETTY PLEASE WITH cinnamon & BROWN-SUGAR ON TOP LET IT NOT BE A yats.

Seems any of the other PCB vendors that offer a full-SMD project for the first time it's always a yats.

I really am sorry, I have failed you....

Feral Feline

Well-known member

I really am sorry, I have failed you....

So no Kemper?

I'll have my crew sort you out for that.

To be honest, I'd already seen that in the shop's pages before I posted.

I'd just forgotten about it.

PS: But it proves my point — they all offer YATS in SMD before any other circuit....