Phasma888

Member

Have a nice day, everyone!

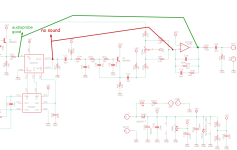

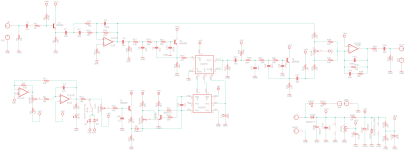

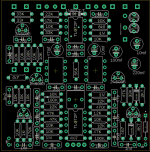

Please help if you can - the Caesar chorus part is not working.

Try to ignore the voltage and op amp names in schematic - it just fits.

I hope it will be easier than 23 wounds.

3207 voltages

1) 0.00 8) 3.95

2) 4.20 7) 3.95

3) 1.06 6) 4.17

4) 8.06 5) 8.64

All LEDs (and 3mm) work as they should, 5mm are temporarily not soldered. The flashing frequency is successfully adjusted by pots.

UPD: the blend pot works like a reverse volume - at the max the sound disappears, at low values - quite loudly.

Please help if you can - the Caesar chorus part is not working.

Try to ignore the voltage and op amp names in schematic - it just fits.

I hope it will be easier than 23 wounds.

3207 voltages

1) 0.00 8) 3.95

2) 4.20 7) 3.95

3) 1.06 6) 4.17

4) 8.06 5) 8.64

All LEDs (and 3mm) work as they should, 5mm are temporarily not soldered. The flashing frequency is successfully adjusted by pots.

UPD: the blend pot works like a reverse volume - at the max the sound disappears, at low values - quite loudly.

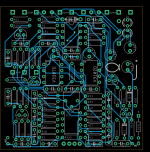

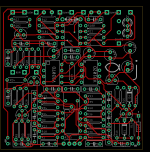

Attachments

Last edited: