TucsonSean

Active member

Hello Everyone,

So, I didn't know if I am putting this in the right location but if not, please let me know where it needs to be moved to.

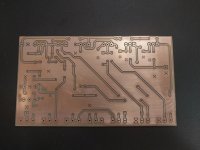

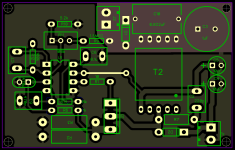

I have been working on a various different preamp pedals for the last several years and I have finally moved forward on one design that I have been kicking around since I built a couple of Particle Accelerator pedals and modified a Mofeta to sound like a Plexi. I have just finished milling one of the PCBs and am working on milling the final PCB. Next steps will be to build up the boards and mill the enclosure.

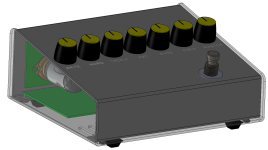

For a teaser, here is the mock-up of the pedal I did in Solidworks so I can mill the enclosure. It is a little larger of a design using a Hammond 1456FE1 enclosure but I think it warrants it. I will be adding to this build report as I complete more of design. And yes to confirm, it is an all tube Plexi pedal using three 12AX7 tubes. No power amp since I use an HX Stomp XL for my cab sims for my rig. I'm hoping this will give the best of both worlds: feel and sound of tubes with convenience of cab sims and effects. I don't want to give too much away on this since I haven't seen another design like it yet but as soon as I verify the complete design, I will share the full schematic.

-Sean

So, I didn't know if I am putting this in the right location but if not, please let me know where it needs to be moved to.

I have been working on a various different preamp pedals for the last several years and I have finally moved forward on one design that I have been kicking around since I built a couple of Particle Accelerator pedals and modified a Mofeta to sound like a Plexi. I have just finished milling one of the PCBs and am working on milling the final PCB. Next steps will be to build up the boards and mill the enclosure.

For a teaser, here is the mock-up of the pedal I did in Solidworks so I can mill the enclosure. It is a little larger of a design using a Hammond 1456FE1 enclosure but I think it warrants it. I will be adding to this build report as I complete more of design. And yes to confirm, it is an all tube Plexi pedal using three 12AX7 tubes. No power amp since I use an HX Stomp XL for my cab sims for my rig. I'm hoping this will give the best of both worlds: feel and sound of tubes with convenience of cab sims and effects. I don't want to give too much away on this since I haven't seen another design like it yet but as soon as I verify the complete design, I will share the full schematic.

-Sean