fancypete

Member

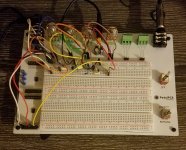

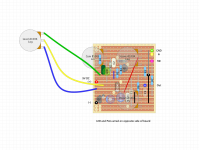

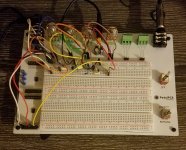

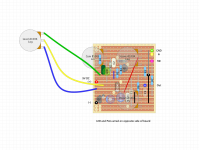

Well I took the Plecostomus fuzz that I tested on my protoboard and made a layout using DIYLC. It was a super fun puzzle experience. I decided to make it challenging by fitting it all onto a 17x19 piece of strip board. After about a day of doing the layout ( I finally surrendered and just wired the Level pot off-board) I transferred the components onto the strip board. Everything went together smoothly. I boxed it up, plugged it in, and the dang thing sounded great! For five minutes...then it stopped working. But it DID work! Now I'm looking forward to tearing it apart and figuring out what the heck is going on. Anyway, at least I confirmed the layout works, even if it is a bit cramped. What a fun activity. Really makes me appreciate the great layouts PedalPCB provides with their pcbs.