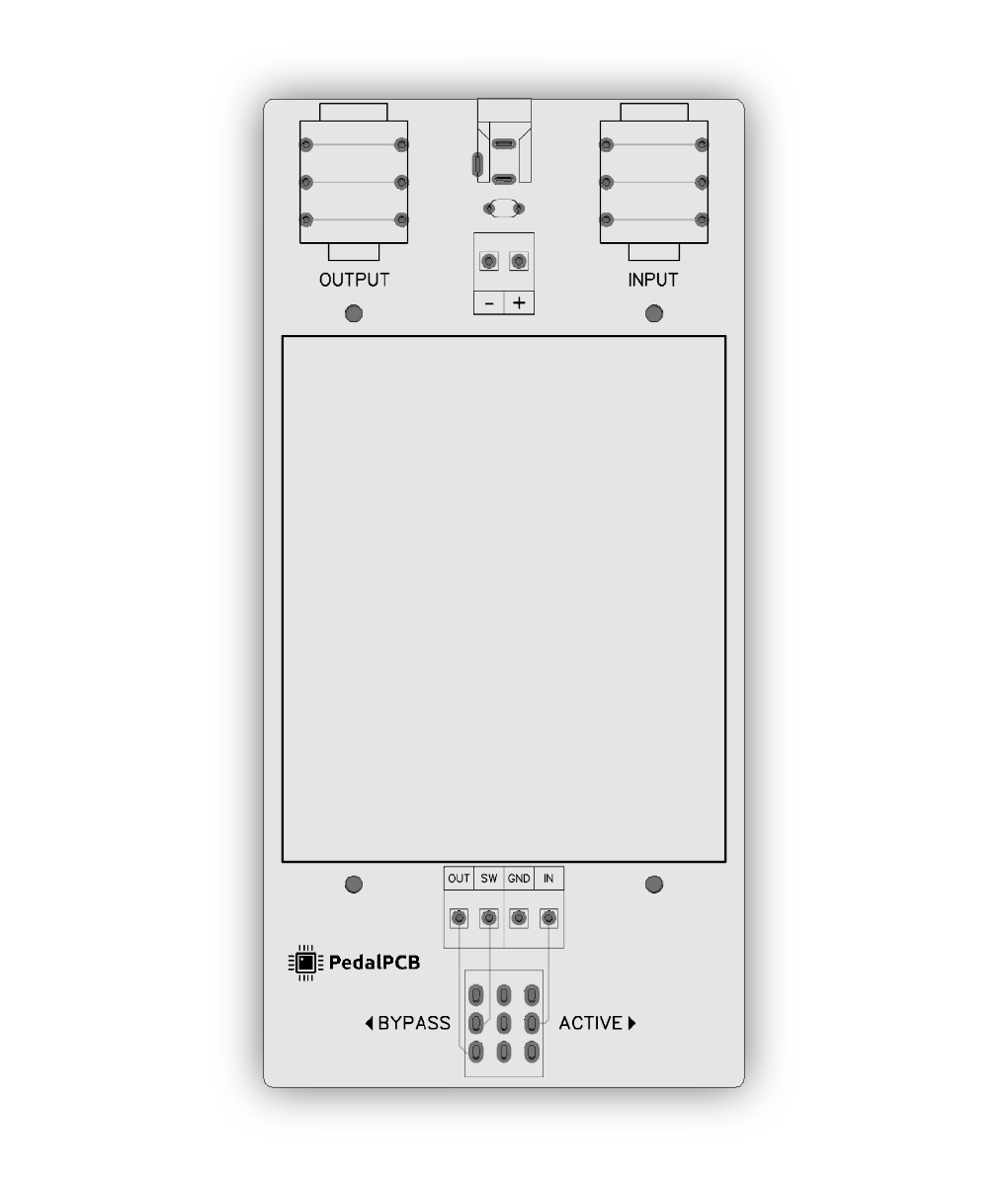

I currently use the type of connector below. Unfortunately, you can’t remove it without unsoldering, which often destroys the plug.

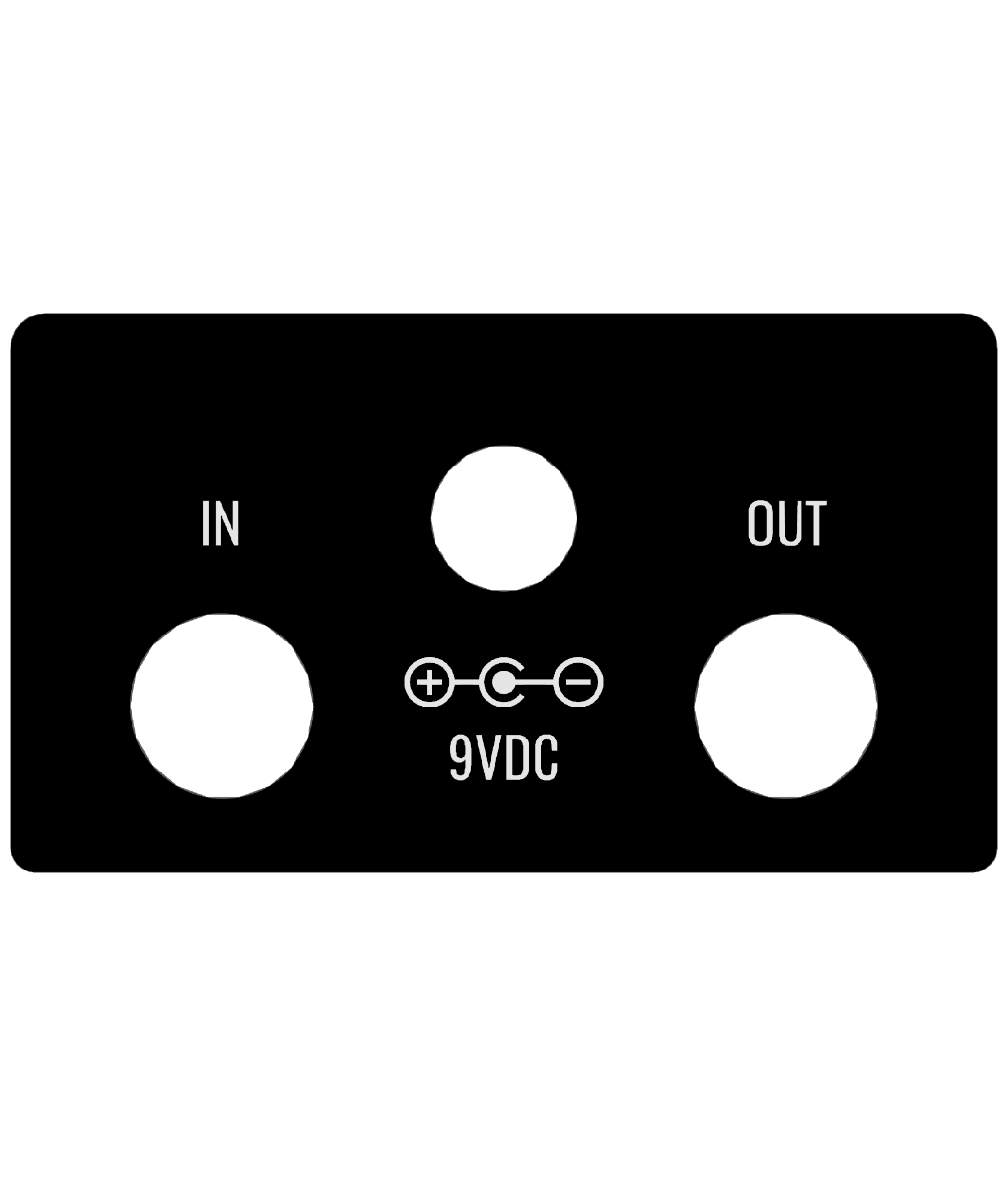

As I have most of my pedals unlabeled, waiting to get a few more done to maximize use of the sheets. As such I’m likely going to have to remove everything to apply decals/clearcoat.

That said, has anyone used spade connectors to attach to the jack, or something like a micro wago connector (if it exists)?

As I have most of my pedals unlabeled, waiting to get a few more done to maximize use of the sheets. As such I’m likely going to have to remove everything to apply decals/clearcoat.

That said, has anyone used spade connectors to attach to the jack, or something like a micro wago connector (if it exists)?