I recently completed a build of the Silismile fuzz. I want to modify it by removing the internal trim pot for biasing the transistors and replacing it with an external pot. I know I will desolder the current bias pot and will solder in 3 wires that I will connect to the external pot. I am a noob at this and I can’t find any documentation telling me exactly how to wire it? Can anyone spell it out for me? Also I have seen that some people have used a 20k pot vs 10k… any pluses or minuses for either option? Recommendations?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Silismile external transistor bias trim pot

- Thread starter Drlufk00

- Start date

Feral Feline

Well-known member

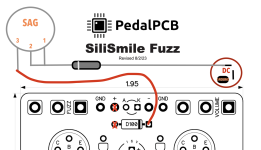

It also kinda depends on how you prefer to think about it...

Like, turning the pot CW to allow more juice through it, or do you think of the pot as turning it CCW for less restriction to the flow of juice (ie current)?

If you want to keep it like the schematic and the way the board is laid out, the trimmer's legs are 1>2>3 left-to-right looking in the back of the enclosure at the populated PCB's guts — but looking in though the back door the external pots' legs are numbered 3>2>1 from left-to-right.

So to wire the external pot and have it operate the same as the internal trimmer did, you'll cross the wires...

Bonus points if you make it a 4-pot fuzz...

If the SAG doesn't behave the intuitive way you think the pot should rotate, swap the outer lugs (for below, you'd connect SAG 3&2 to the Diode and SAG1 would go to the board).

PS: It was brought to my attention by Jwin (see post below) that the BIAS' lugs 3&2 are tied — duh! Wasn't awake yet... so yeah, that's my story and I'm stickin' twit...

REVISED:

Like, turning the pot CW to allow more juice through it, or do you think of the pot as turning it CCW for less restriction to the flow of juice (ie current)?

If you want to keep it like the schematic and the way the board is laid out, the trimmer's legs are 1>2>3 left-to-right looking in the back of the enclosure at the populated PCB's guts — but looking in though the back door the external pots' legs are numbered 3>2>1 from left-to-right.

So to wire the external pot and have it operate the same as the internal trimmer did, you'll cross the wires...

Bonus points if you make it a 4-pot fuzz...

If the SAG doesn't behave the intuitive way you think the pot should rotate, swap the outer lugs (for below, you'd connect SAG 3&2 to the Diode and SAG1 would go to the board).

PS: It was brought to my attention by Jwin (see post below) that the BIAS' lugs 3&2 are tied — duh! Wasn't awake yet... so yeah, that's my story and I'm stickin' twit...

REVISED:

Last edited:

Only need 2 wires. Lugs 2 and 3 are numbered on the trimmer. Make the same jumper on the pot.

And inline resistor isn't a bad idea to increase usable range. Turn the trimmer to the lowest resistance between pin 1 and 2 that still passes usable audio. Measure and put a value close/just under that value to that inline with your wiring

And inline resistor isn't a bad idea to increase usable range. Turn the trimmer to the lowest resistance between pin 1 and 2 that still passes usable audio. Measure and put a value close/just under that value to that inline with your wiring

So, run a wire from 1 to 1 , 2 to 2 and add a jumper between lugs 2 and 3 on the pot while leaving the 3 terminal open on the pcb?Only need 2 wires. Lugs 2 and 3 are numbered on the trimmer. Make the same jumper on the pot.

And inline resistor isn't a bad idea to increase usable range. Turn the trimmer to the lowest resistance between pin 1 and 2 that still passes usable audio. Measure and put a value close/just under that value to that inline with your wiring

Yes. If you look at the schem, 2 and 3 are shorted on the PCB. This is wiring it as a variable resistor.

You can just strip a bit more wire feed it through 2 over to 3 or vise versa.

I would add resistance, and maybe drop the value of the pot if the resistor is large enough

Otherwise you may find only a percentage of the pot as usable.

You can just strip a bit more wire feed it through 2 over to 3 or vise versa.

I would add resistance, and maybe drop the value of the pot if the resistor is large enough

Otherwise you may find only a percentage of the pot as usable.

Run the resistor between 2 and 3? I am just starting on this pedal build journey so it’s all a little deep for me right now… sorry. What value resistor would you recommend?Yes. If you look at the schem, 2 and 3 are shorted on the PCB. This is wiring it as a variable resistor.

You can just strip a bit more wire feed it through 2 over to 3 or vise versa.

I would add resistance, and maybe drop the value of the pot if the resistor is large enough

Otherwise you may find only a percentage of the pot as usable.

The resistor would need to be in series with one of the wires to the pot.

You'll have to do some work to find the value.

Install the pot as described.

Find the minimum position on the pot that's usable. Measure the resistance between pins 1 and 2.

Then do the same at the maximum position that sounds good/usable.

Say you have a 20k pot and it sounds good between 7k and 17k.

Ultimately you'll want to replace that with a 7k resistor and 10k pot.

If it's good from 11k to 17k, you may want a 10k resistor and 10k pot, and the first 10% and last 20% of the pots throw may not produce sound. But that's better than the first 55% and last 5%.

You goal is to get usable sound out of most of the pot's throw/travel, without ommiting a resistance range you desire to be accessible. Say, a 5k resistor and a 10k pot, which would omit the desired 15k-17k range.

Hope that makes sense and good luck. If you find you're desired min-max resistance, post it.

You'll have to do some work to find the value.

Install the pot as described.

Find the minimum position on the pot that's usable. Measure the resistance between pins 1 and 2.

Then do the same at the maximum position that sounds good/usable.

Say you have a 20k pot and it sounds good between 7k and 17k.

Ultimately you'll want to replace that with a 7k resistor and 10k pot.

If it's good from 11k to 17k, you may want a 10k resistor and 10k pot, and the first 10% and last 20% of the pots throw may not produce sound. But that's better than the first 55% and last 5%.

You goal is to get usable sound out of most of the pot's throw/travel, without ommiting a resistance range you desire to be accessible. Say, a 5k resistor and a 10k pot, which would omit the desired 15k-17k range.

Hope that makes sense and good luck. If you find you're desired min-max resistance, post it.

Does it matter which wire I put the resistor on? Could I solder one leg of the resistor to the pot lug and the other to a wire connected to the corresponding spot on the pcb? Or do I need to go pot lug~wire~resistor~wire~pcb? Anyone have a schematic? I produce CAD drawings all day so I am a terribly visual person. If I have a 10k pot it would still work in the same principle… say I find the usable sound to be between 3 and 8k would I need to drop to a 1k pot with an 8k resistor? Or would I just be better off leaving the 10k pot alone and losing the 30% on the bottom and 20% on the top? Is it even worth measuring the resistance with a 10k?The resistor would need to be in series with one of the wires to the pot.

You'll have to do some work to find the value.

Install the pot as described.

Find the minimum position on the pot that's usable. Measure the resistance between pins 1 and 2.

Then do the same at the maximum position that sounds good/usable.

Say you have a 20k pot and it sounds good between 7k and 17k.

Ultimately you'll want to replace that with a 7k resistor and 10k pot.

If it's good from 11k to 17k, you may want a 10k resistor and 10k pot, and the first 10% and last 20% of the pots throw may not produce sound. But that's better than the first 55% and last 5%.

You goal is to get usable sound out of most of the pot's throw/travel, without ommiting a resistance range you desire to be accessible. Say, a 5k resistor and a 10k pot, which would omit the desired 15k-17k range.

Hope that makes sense and good luck. If you find you're desired min-max resistance, post it.

Feral Feline

Well-known member

The electrons flying around the circuit aren't going to know or care whether it's

The Schematic is in the build doc.

If you really wanted to you could put a 3k resistor on leg3 of the pot (3 tied to 2), another 2k resistor on pot's leg1 and run those resistors to the corresponding trimmer pads on the PCB — with a B5k-pot you'd be basically right in the sweet spot and have usefulness for the full range of the pot.

pot-lug>resistor>wire>PCB

orpot-lug>wire>resistor>wire>PCB

The Schematic is in the build doc.

If you really wanted to you could put a 3k resistor on leg3 of the pot (3 tied to 2), another 2k resistor on pot's leg1 and run those resistors to the corresponding trimmer pads on the PCB — with a B5k-pot you'd be basically right in the sweet spot and have usefulness for the full range of the pot.