Paul.Ruby

Well-known member

Yep. You can plug in just about anything.Could you plug in a preamp pedal/modeler like a Dream65?

oooo boards??

You have a Volume only one coming? You selling the TMB version?

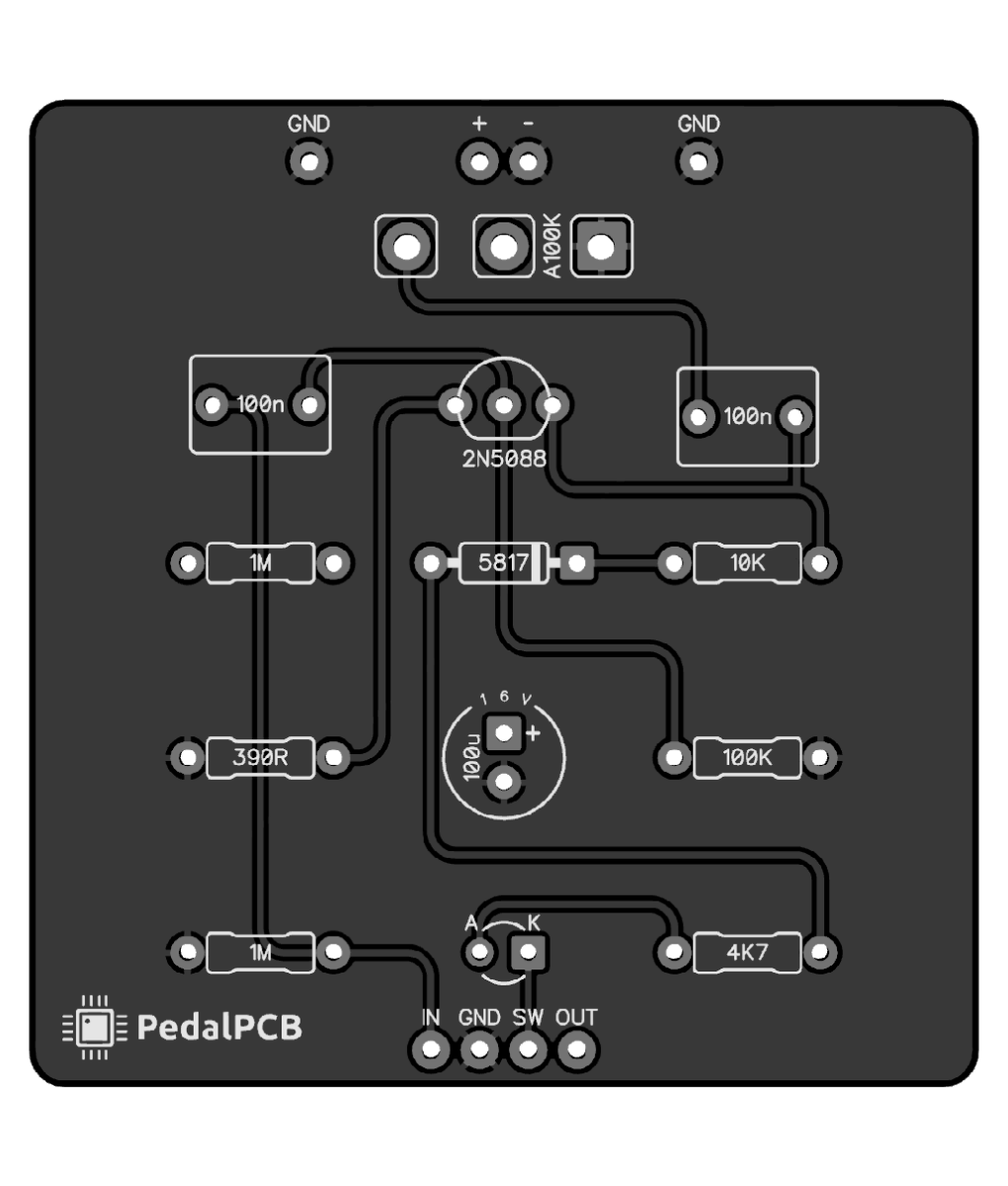

I have 6 different boards coming... They are split into either TMB or Volume only. And then each of those has 3 different methods of soft-touch mute: Digispark; Direct ATtiny chip; or discrete components to implement it. I ordered 10 of each because the boards are really cheap. Shipping costs more than all 10 boards. So... I will have a pile to share with folks who want to try them out.