CheapSuitG

The TubeSchemer

Hi!

I’m building a pedal for a friend who’s a bust touring musician as a gift. While he’s not abusive with his gear, he is an enthusiastic performer so I want to make sure this build is as bulletproof as possible.

Up to now, I’ve only built pedals for myself and a couple of local friends, nothing that’s really seen life on the road.

I plan on using high end jacks, switches, pots etc.

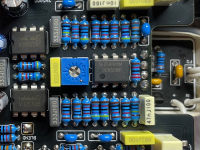

I usually socket ICs to avoid heat damage while soldering but for something that’s going to be bounced around a lot, is there a good way to secure them in their sockets so they don’t come loose over time?

Any other tips?

Thanks!

I’m building a pedal for a friend who’s a bust touring musician as a gift. While he’s not abusive with his gear, he is an enthusiastic performer so I want to make sure this build is as bulletproof as possible.

Up to now, I’ve only built pedals for myself and a couple of local friends, nothing that’s really seen life on the road.

I plan on using high end jacks, switches, pots etc.

I usually socket ICs to avoid heat damage while soldering but for something that’s going to be bounced around a lot, is there a good way to secure them in their sockets so they don’t come loose over time?

Any other tips?

Thanks!