comradehoser

Well-known member

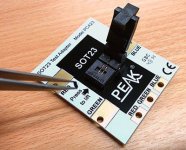

I don't know about you, but I want to invest as little as possible in SMD transistors and their accoutrements. I really dislike working with them. Maybe even loathe it. I found *one* SMD J201 out of a batch of 20 that I could pair at .93 IDSS with a .90 IDSS I had already soldered in my Deofol rework. Sure enough, it wasn't lining up to solder, I was moving it with needlenose tweezers, and it pinged right off the board, off my shirt, and into effing oblivion. So now I have to order another batch of 10 mmbfj201 and hope that one of them is >.90 IDSS