RobotZombie23

Member

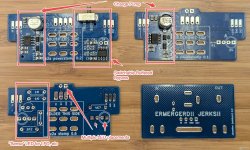

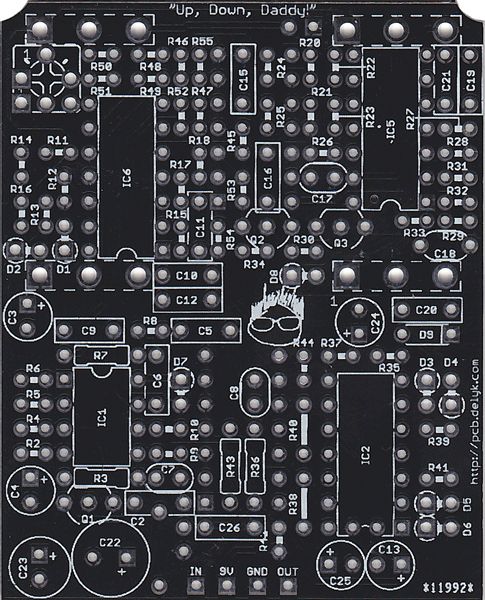

"Up, Down, Daddy!" PCB - delyk PCBs

My daughter melts my heart when she asks me to "Up, Down, Daddy!" when throwing her up into the air and catching her. I figured this was a perfect name for an octaver with 1 octave up and 1 and/or two octaves down.

I made one of these boards a couple years ago. I want to make another since I think I'm better at making pedals now. The thing with this one is that its really close quarters when building it. it's a real PITA. Plus it's been sold out for a while. Is there any other board makers with this circuit? (Pearl OC-07) Or maybe someone can fire up KiCad and whip something up? I'd buy one. I don't think this is the circuit to try and learn KiKad with. I really like the sound of it before a nice fuzz...nice and doomy