Paul.Ruby

Well-known member

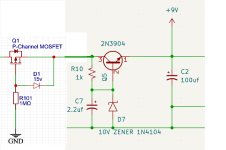

I just saw a post over on the gear page about folks blowing up their KTR by applying 18V accidentally. IMO, pedal makers should expect such a thing to happen and handle it gracefully. The common voltage doubler chips have a max operating voltage of 10V. Pedals that use them usually have a zener diode to shunt away the high voltage. But, those burn up and don't really provide any protection. They will either short or open, both of which is fatal to the pedal. I've added this to my muzzle builds to keep the voltage under about 9.6V, even if the input is 18V. This came in handy for my combo-build that has a muzzle but also includes other modules that I prefer to have 15V. Dirt simple linear regulator.

Last edited: