Brett

Well-known member

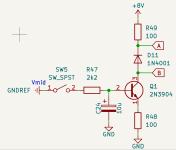

It's probably safe to assume that when you're switching contacts at half the current (36mA vs. 72mA) with the high-sensitivity type (denoted by the "S" in the part number) it's going to result in less noise.For some reason, they are totally quiet.

Edited to say that I have had zero switching noise that gets into the audio path using cheap low-profile relays, at least so far.