jessenator

Well-known member

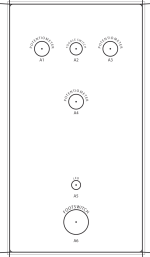

parts washer tub heredrill press setup inside a mortar mixing tub

IDK if it was the cold, but my formerly-trusty PLA drill template did not hold up during its last (and final) run. Would do PETG, but every time I think I have the settings dialed in it turns into a stringy mess that detaches from the build plate. Also thought about tapering the tops of the holes to match the angle of the punch I have. Maybe both.