matthewmcmahonsf

New member

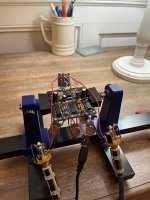

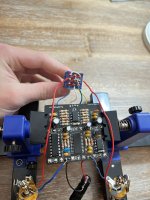

I built a PedalPCB Deflector Reverb pedal for my electronics project in school and it is due tomorrow and need to know if this solder burn has ruined my pedal for the good. I also think that the issue may be my soldering tactics for the potentiometers, but I can't tell. It is a Deflector Pedal PCB and when I turn the pedal on the guitar can run through it perfectly fine and two of the potentiometers make some weird noise but there is definitely no reverb and the circuit isn't working. Basically, when everything is plugged in, the light turns on when I press the switch and the guitar signal runs through the circuit because I can hear the guitar in the amp. The 25K potentiometers make a ringing noise that has no effect on the guitar signal itself, but every other potentiometer does absolutely nothing. There is basically no effect when I run turn the switch on except for the signal gets a little bit louder.