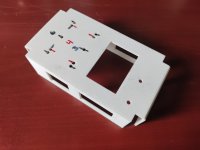

Paper templates. Hand drill. Step bit. On a flat surface. Painters tape on the enclosure, to prevent sliding, or scratching while drilling.

I scrape the step bit with a 3.5” deck screw between drilling holes. The residual aluminum clings to the bit and can/will mess up a new hole. I use the same screw to tap, with a hammer, a pilot hole.

Without a pilot hole the first rotations of the bit will slide. And even a few mm’s of center is annoying, obviously.

I’ve gotten better at drilling, the first few were a little wonkey, and non symmetrical.

If and when I step up production, I will acquire a drill press.

Labeling is a separate challenge.

I am currently using alcohol ink and rubber stamps. And I use a toothpick, dipped in ink to hand write any touch ups. It took me a long time to decide on a method. It’s not for everyone, and it’s rather minimalist. But I like the look.

Good luck with the CAD stuff. I chose the ink label method because I thought it would be more hands on, simple, cheap and fast.

And… if I repurpose an enclosure, I can remove the ink and re-label it.