finebyfine

Well-known member

- Build Rating

- 5.00 star(s)

I was finally able to finish setting up my full size protoboard, and I really cannot sing high enough praise of this. Super grateful to have gotten it in one of the anniversary contests.

Let me start by saying that I truly hate breadboarding. I find it tedious, frustrating, messy, to say nothing of it feeling physically challenging finessing wires. My bench is not big and it gets unruly quick with a breadboard and wires strewn all over the place. I am not a "learn by messing things up" type learner (or rather, I prefer to have a ton of preparation for that part) and a breadboard might as well be a mortal enemy to that trait. I wish I could see a breadboard as a playground of wonder the way I know some people into electronics do. Instead I feel like a toddler ready to flip over a game board.

Because I hate breadboarding but have experienced how essential of a skill it is in a hobby that I enjoy more than anything on the planet, I have done and tried tons of things to reduce my inertia. Premium dupont jumpers? (Color coded, of course, so that I can remember what they're doing), every kind of breadboard adapter known to man, color coded breadboards themselves, soldering my own breadboard with machined IC sockets to try to get better lead grabbing strength, 3d printed wire cutting jigs for 2.54mm spacing, crimping my own 1 inch jumpers - you name it - I have tried it, with at best, alright results.

I'm not going to suggest that the protoboard has made me do a complete 180 but having one setup with high quality breadboards screwed into the board is probably the biggest inertia reducer I've had yet. Having the kinds of power circuits that I end up setting up on most breadboards anyway (charge pump, vref, etc) makes it easier to just jump into the circuit.

I ordered a big handful of breadboards to try to find one that was better than any I've used and I could also mount with screws to the board. I had experience with Bus Boards, which are nicer than the MB-102 from Tayda that is ubiquitous but really had it start to come together when I tried a few from Global Specialties - I have two of the GS-770 installed and they're the most secure without needing excessive force to remove I've come across. I liked all that I tried but only the GS-770's mounting holes lined up with the pcb, but I had to bore out the mounting holes a hair.

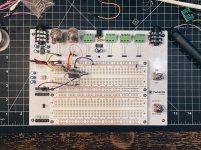

Picture shows an in progress LM1700 ring modulator circuit that I've been working on adapting to just be an octave up - had to leave for work soon after taking the photo and there are some wrong connections so don't look too carefully!

Let me start by saying that I truly hate breadboarding. I find it tedious, frustrating, messy, to say nothing of it feeling physically challenging finessing wires. My bench is not big and it gets unruly quick with a breadboard and wires strewn all over the place. I am not a "learn by messing things up" type learner (or rather, I prefer to have a ton of preparation for that part) and a breadboard might as well be a mortal enemy to that trait. I wish I could see a breadboard as a playground of wonder the way I know some people into electronics do. Instead I feel like a toddler ready to flip over a game board.

Because I hate breadboarding but have experienced how essential of a skill it is in a hobby that I enjoy more than anything on the planet, I have done and tried tons of things to reduce my inertia. Premium dupont jumpers? (Color coded, of course, so that I can remember what they're doing), every kind of breadboard adapter known to man, color coded breadboards themselves, soldering my own breadboard with machined IC sockets to try to get better lead grabbing strength, 3d printed wire cutting jigs for 2.54mm spacing, crimping my own 1 inch jumpers - you name it - I have tried it, with at best, alright results.

I'm not going to suggest that the protoboard has made me do a complete 180 but having one setup with high quality breadboards screwed into the board is probably the biggest inertia reducer I've had yet. Having the kinds of power circuits that I end up setting up on most breadboards anyway (charge pump, vref, etc) makes it easier to just jump into the circuit.

I ordered a big handful of breadboards to try to find one that was better than any I've used and I could also mount with screws to the board. I had experience with Bus Boards, which are nicer than the MB-102 from Tayda that is ubiquitous but really had it start to come together when I tried a few from Global Specialties - I have two of the GS-770 installed and they're the most secure without needing excessive force to remove I've come across. I liked all that I tried but only the GS-770's mounting holes lined up with the pcb, but I had to bore out the mounting holes a hair.

Picture shows an in progress LM1700 ring modulator circuit that I've been working on adapting to just be an octave up - had to leave for work soon after taking the photo and there are some wrong connections so don't look too carefully!