coccoslash

New member

Hi everyone.

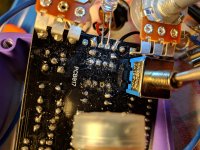

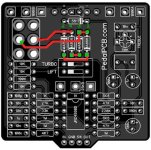

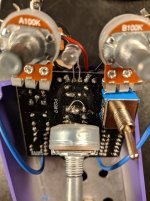

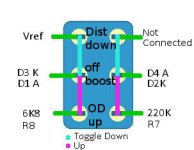

I have a problem on the Pauper. I think I burned the pads where the diodes are soldered (I did various tests changing from Ba283s to 4148s..and I did the damage). Practically the on/off/on selector no longer works. Acting on the switch, the pedal always remains only in the OD position (I think ... or maybe DIST).

Is there a way to bypass the PCB and attach the diodes directly to the switch? Or other solutions?

Thanks so much

I have a problem on the Pauper. I think I burned the pads where the diodes are soldered (I did various tests changing from Ba283s to 4148s..and I did the damage). Practically the on/off/on selector no longer works. Acting on the switch, the pedal always remains only in the OD position (I think ... or maybe DIST).

Is there a way to bypass the PCB and attach the diodes directly to the switch? Or other solutions?

Thanks so much