jameuwissen

New member

I appreciate everyone's input here. 15 seconds is definitely an outlier, but something does seem off as it is always definitely more than the 1-3 seconds per lead. And yes, Darwin- that is the correct solder, but I have it in 0.8mm. I never really considered that, but especially for lead free, should I look at getting 3mm? Would be easier to transfer heat, take less time to get a smaller mass of wire to melt, right?

For my own learning, just I want to summarize a few things to make sure I'm understanding and thinking this through correctly- Is it possible that even though my irons thermostat reads >830 F, that due to some combination of a dirty/oxidized/spent tip and some even mild inaccuracies in my irons thermostat I may be actually transferring a more "appropriate" amount of heat (at the expense of efficiency and probably oxidizing the tip), and actually be OK for the component? At this point, I no doubt need good, quality practice with a soldering iron. I would definitely trade buying a few extra soldering tips while learning than ruin components/boards.

Until I figure out this heat issue and improve my technique, I want to test the components one at a time as I apply them. I figure take the time and be patient early to prevent more frustrating troubleshooting later, especially if the heat is impacting the components.

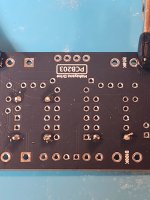

Regarding that, another novice question - I tested the three 1k resistors in the attached pics (havent trimmed the extra leads yet) with a Fluke 70 series ii multimeter, they are coming out reading OK (998 for 1k's with 1% tolerance). So..... am I right in that they seem to be OK and survived my soldering? To my beginner eyes, the board and the components seem to be OK, visually.

To follow up, as I get into adding and testing the caps and other components, would testing continuity between the leads of the individual component be best? Basic question, I know, I just want to make sure I'm going about this correctly.

Again, thanks so much for all of your time and responses.

For my own learning, just I want to summarize a few things to make sure I'm understanding and thinking this through correctly- Is it possible that even though my irons thermostat reads >830 F, that due to some combination of a dirty/oxidized/spent tip and some even mild inaccuracies in my irons thermostat I may be actually transferring a more "appropriate" amount of heat (at the expense of efficiency and probably oxidizing the tip), and actually be OK for the component? At this point, I no doubt need good, quality practice with a soldering iron. I would definitely trade buying a few extra soldering tips while learning than ruin components/boards.

Until I figure out this heat issue and improve my technique, I want to test the components one at a time as I apply them. I figure take the time and be patient early to prevent more frustrating troubleshooting later, especially if the heat is impacting the components.

Regarding that, another novice question - I tested the three 1k resistors in the attached pics (havent trimmed the extra leads yet) with a Fluke 70 series ii multimeter, they are coming out reading OK (998 for 1k's with 1% tolerance). So..... am I right in that they seem to be OK and survived my soldering? To my beginner eyes, the board and the components seem to be OK, visually.

To follow up, as I get into adding and testing the caps and other components, would testing continuity between the leads of the individual component be best? Basic question, I know, I just want to make sure I'm going about this correctly.

Again, thanks so much for all of your time and responses.

Attachments

Last edited: