"End-Mill Bits" are what I look for when counterboring.

In my experience, they are not easy to find because

A) They're scarce

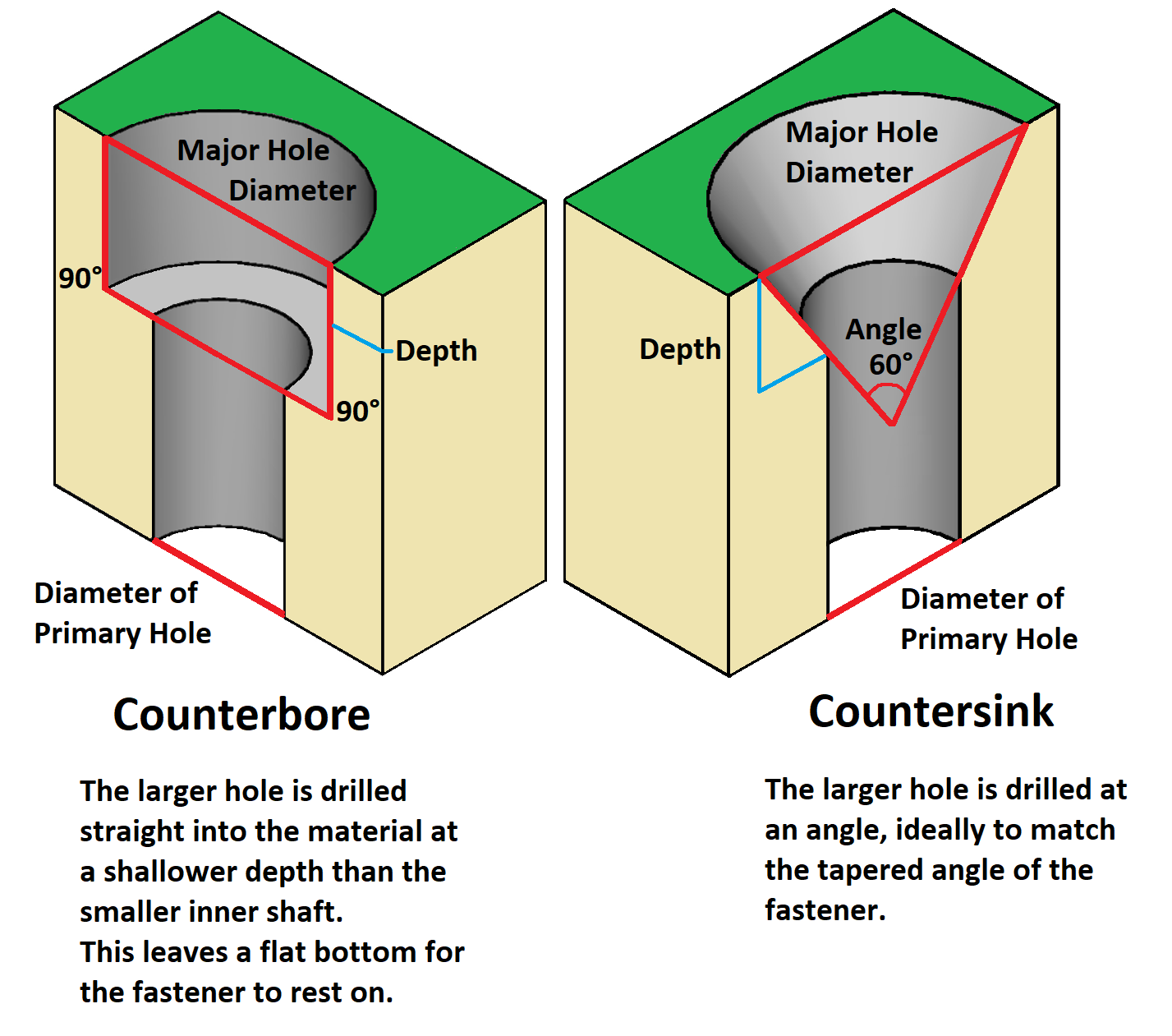

B) Sales-people think I'm asking for a counter-sink bit — which I DON'T WANT.

I can never remember the correct terminology for the "end-mill bits" when I'm hunting for them, which lead to a lot of the sales-staff at hardware stores giving me that "

you don't know WTF you're talking about, dipstick, here's what you want/need — a countersink-bit."

Then we both walk away from each other rolling our eyes...

Hard to describe what you want/need to someone when they've already made up his/her mind about what you want/mean.