chongmagic

Well-known member

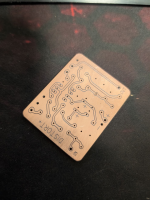

Decided to get a fiber laser and didn't even think about making your own PCBs, has anyone tried this?

It should be here in a few days. I want to try engraving some pedals with it for sure. I'm super excited to try it out for sure!There’s a good amount of videos around about people doing it, it’s surely doable. Seems like a lot of hassle to me with drilling and solder mask/silkscreen curing etc. cool though! Have you done anything with the laser yet??

Ordering PCBs ... pffft... LAZY!

Nothing as satisfying as MAKING YOUR OWN PRINTED CIRCUIT BOARDS! AhmmahRight, Chongmagic?

Gotta roll your own PIO caps as well... smelt the leads yourself... personally mine the tantalum for those tant-caps... then power the whole shebang from your own windmill farm where each fan blade doubles as a solar-panel... so much fun, so much to DO when you go TRULY DIY!

On second thought, I'm just going to get a Mooer-clone off Tao-bao for like... $30 including shipping. Then I won't need to debug my builds anymore...

Have fun with your new toy, Chongmagic!

I have a 20W fiber laser (Xtools F1 Ultra) and tried a PCB once, but I wasn't able to get a usable result out of it. I saw a tutorial where someone with the same machine made a PCB, but all the comments were from people that tried it and weren't able to get it to work.Decided to get a fiber laser and didn't even think about making your own PCBs, has anyone tried this?

Yeah I know it's a ton of work, but it looks so fun to do! And the act of figuring out the correct power settings and speed, I love stuff like that.Just cutting tracks? Easy.

However the whole process is:

As well as having to figure out speeds and power for all these processes which are different?

- cut tracks

- cut half through-holes

- cut positioning jig

- removing board, cutting rear tracks

- applying UV-cure solder mask to both sides

- removing solder mask from both faces

- cutting through-holes all the way through

- cutting board outline

Much easier just to click a single button and have 5 for $5 from PCBWay