New member here.

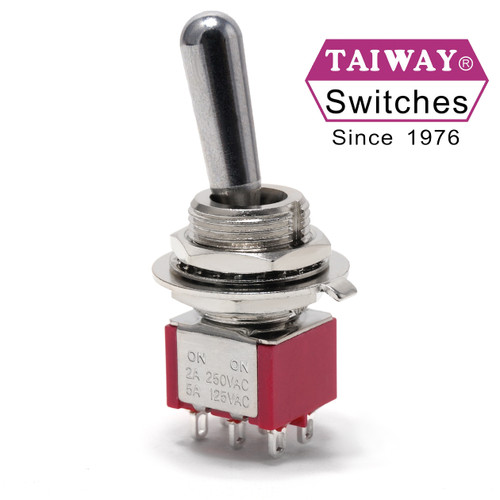

If this has been addressed elsewhere please direct me to it. I want to build my first pedal, probably a Golden Fleece. But the typical footswitch requires too much pressure for my intended application. I’ve been building cigar box guitars and I want to include a single knob effect inside of the guitar body. I’d need to switch it on and off with my hand (not my foot!) Has anyone replaced the foot switch with a toggle switch? Any advice on the appropriate switch and wiring (or warnings not to attempt because…) would be appreciated.

If that doesn’t seem plausible does anyone know of a really light action foot switch?

If this has been addressed elsewhere please direct me to it. I want to build my first pedal, probably a Golden Fleece. But the typical footswitch requires too much pressure for my intended application. I’ve been building cigar box guitars and I want to include a single knob effect inside of the guitar body. I’d need to switch it on and off with my hand (not my foot!) Has anyone replaced the foot switch with a toggle switch? Any advice on the appropriate switch and wiring (or warnings not to attempt because…) would be appreciated.

If that doesn’t seem plausible does anyone know of a really light action foot switch?