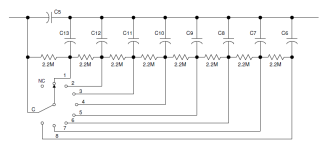

It's a good old Cry-Baby! Pretty much the original circuit, with some trimpots and a DIP switch for the range capacitor. With all of the switches open, this pedal will reach up into dog-whistle territory. I modded my Dunlop Cry-Baby and tweaked most of the stuff that's tweakable here. Stock is about midway on all three trimpots. The LOW trim will affect the bottom end of the sweep range and the gain across the board. The MID trim is pretty subtle. It is important to use quality film caps, except C2 (ceramic or mica), C4 (tantalum) & C100 (aluminum). Get a good WAH pot, Hot Potz, for instance, and take time to properly mechanically align it. A cheap WAH pot will not give the full sweep range and will wear out quickly.

One more thing, this is the unbuffered version of the circuit. When Dunlop took over production of the Cry-Baby in the early '80s, they added an emitter-follower buffer at the front-end because the input circuit does two things that may or may not be desirable:

1) it loads whatever is driving it

2) it is influenced by the output impedance of whatever is driving it

Turning the VOL trimpot clockwise will accentuate both of those factors.

Not a criticism of the circuit design, just a heads-up so you know what to expect.