Cybercow

Well-known member

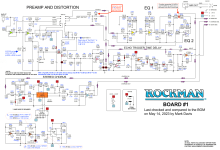

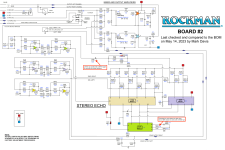

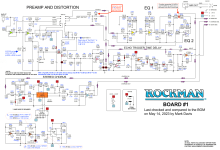

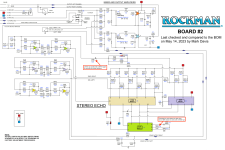

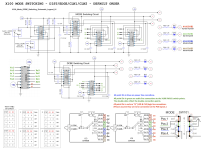

With the successful completion of the (Rockman) RMS X100 Rehouse Project V1 & V2, Josh Ledford and I are happy to finally release the fully corrected Rockman X100 Rev 10 circuit schematics. Over the course of almost four years, as many as four people have collaborated with analyzing, testing, measuring and drawing out the many details wrapped inside Tom Scholz’s signature sound circuit.

The original schematics found on the US Patent site are by no means complete, accurate or even workable when compared to what we eventually discovered with all of the analysis we’d completed on over 2 dozen Rockman X100 units. The attached schematics are accurate, tested and verified as we’ve produced over 40 of the RMS Rockman X100 builds.

(The blue component IDs are those IDs used on our V1, V2 & V3 PCBs. The IDs in black are those used on the original 1980s X100 rev 10 boards.)

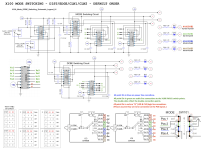

The first 18 months or so was spent on analysis, schematic corrections & creation, cloning the original PCBs and parts sourcing. The original concept was to simply rehouse an X100 into a pedal with foot switches for faster access to MODE & FX changes. After producing a working set of PCBs, populating and successful testing, the next step was to sort out how change the slider switches to stompswitches. But the stompswitches available are just insufficient to meet the complex switching arrangement Scholz used in his units. That was about where I came on board to help with a working, reliable switching system for these pedals. Old school sequential logic switching proved out to be the easiest approach without having 8 or more stompswitches on a pedal to accommodate all the MODES & FX. So, one stomp to cycle thru all four MODES and and one stompswitch to cycle thru the three FX with an added “Dry” option (no FX). Naturally, a true-bypass 4PDT stompswitch was included to facilitate the mono-in/stereo-out circuit.

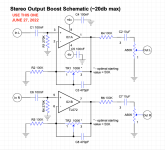

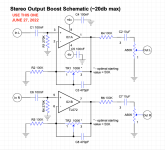

Another discovery with X100 prompted us to develop a unity-gain recapture circuit, as the X100 is a below-unity-gain circuit. So with the switching and output levels to manage, we added the ‘sequential logic switching’ and ‘low-level output’ (LLO) circuits.

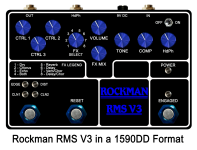

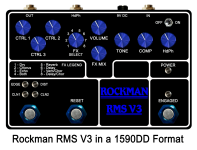

There is a lot to be said about the differences between the original Rockman X100 and the updated V3 units we are about to produce. The evolution from the simple “rehousing” idea to the latest RMS Rockman X100 V3 is another long story that will also unwind as time allows.

With the disappearing availability of the MN3011 BBD chips, we will drop the use of the MN30xx BBD chipsets altogether and use the SpinSemi FV-1 DSP chip. This greatly reduces the overall noise, large footprint & parts-count of the PCB. And it allows us to go with a smaller, more readily available 1590D enclosure, using the same sequential logic switching for the MODE options. The FV-1 FX switching will be a standard SP8T rotary switch. About 6 months was spent in learning and developing the FV-1 FX patches to match the original X100 FX sounds. The bonus with the FV-1 is that it allowed us to add 5 more unique FX patches to the Rockman sound. And we already have a working prototype of the FV-1 infused V3.

For the most part, all is said and done. Except for the completion of the V3 portion of this massive project.

The original schematics found on the US Patent site are by no means complete, accurate or even workable when compared to what we eventually discovered with all of the analysis we’d completed on over 2 dozen Rockman X100 units. The attached schematics are accurate, tested and verified as we’ve produced over 40 of the RMS Rockman X100 builds.

(The blue component IDs are those IDs used on our V1, V2 & V3 PCBs. The IDs in black are those used on the original 1980s X100 rev 10 boards.)

The first 18 months or so was spent on analysis, schematic corrections & creation, cloning the original PCBs and parts sourcing. The original concept was to simply rehouse an X100 into a pedal with foot switches for faster access to MODE & FX changes. After producing a working set of PCBs, populating and successful testing, the next step was to sort out how change the slider switches to stompswitches. But the stompswitches available are just insufficient to meet the complex switching arrangement Scholz used in his units. That was about where I came on board to help with a working, reliable switching system for these pedals. Old school sequential logic switching proved out to be the easiest approach without having 8 or more stompswitches on a pedal to accommodate all the MODES & FX. So, one stomp to cycle thru all four MODES and and one stompswitch to cycle thru the three FX with an added “Dry” option (no FX). Naturally, a true-bypass 4PDT stompswitch was included to facilitate the mono-in/stereo-out circuit.

Another discovery with X100 prompted us to develop a unity-gain recapture circuit, as the X100 is a below-unity-gain circuit. So with the switching and output levels to manage, we added the ‘sequential logic switching’ and ‘low-level output’ (LLO) circuits.

There is a lot to be said about the differences between the original Rockman X100 and the updated V3 units we are about to produce. The evolution from the simple “rehousing” idea to the latest RMS Rockman X100 V3 is another long story that will also unwind as time allows.

With the disappearing availability of the MN3011 BBD chips, we will drop the use of the MN30xx BBD chipsets altogether and use the SpinSemi FV-1 DSP chip. This greatly reduces the overall noise, large footprint & parts-count of the PCB. And it allows us to go with a smaller, more readily available 1590D enclosure, using the same sequential logic switching for the MODE options. The FV-1 FX switching will be a standard SP8T rotary switch. About 6 months was spent in learning and developing the FV-1 FX patches to match the original X100 FX sounds. The bonus with the FV-1 is that it allowed us to add 5 more unique FX patches to the Rockman sound. And we already have a working prototype of the FV-1 infused V3.

For the most part, all is said and done. Except for the completion of the V3 portion of this massive project.