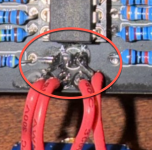

Hello. This is my first build. I’m going to start researching how to troubleshoot this, but maybe there’s something obvious that I did wrong that the pictures reveal.

As I mention in the title, sound passes through fine when bypassed. When I click it on, no LED, no sound.

The power socket was attached, but I removed it so I could take a picture of the back side of the PCB. It was wired correctly afaik.

Any feedback provided is greatly appreciated!

As I mention in the title, sound passes through fine when bypassed. When I click it on, no LED, no sound.

The power socket was attached, but I removed it so I could take a picture of the back side of the PCB. It was wired correctly afaik.

Any feedback provided is greatly appreciated!