jwyles90

Well-known member

Hey all!

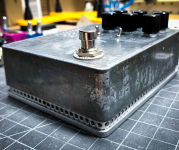

Was drilling some enclosures earlier and to my shock and horror, realized after drilling that my LED hole was way off center. It all looked good when I center punched it, but I suppose I didn’t look closely enough (clearly).

I’m just curious is anyone has any tips or suggestions for possibly refilling the hole, or even partially filling it, to center things out a bit. I saw @MichaelW ‘s thread on borked enclosures, which was super helpful. But I’m wondering if there’s a way to remedy this a bit that wouldn’t require stripping the color off the enclosure.

I also recognize that it might be difficult to do without sanding the front down, so leaning into the wonkiness might be my only option here. Any suggestions or tips would be greatly appreciated though!

Was drilling some enclosures earlier and to my shock and horror, realized after drilling that my LED hole was way off center. It all looked good when I center punched it, but I suppose I didn’t look closely enough (clearly).

I’m just curious is anyone has any tips or suggestions for possibly refilling the hole, or even partially filling it, to center things out a bit. I saw @MichaelW ‘s thread on borked enclosures, which was super helpful. But I’m wondering if there’s a way to remedy this a bit that wouldn’t require stripping the color off the enclosure.

I also recognize that it might be difficult to do without sanding the front down, so leaning into the wonkiness might be my only option here. Any suggestions or tips would be greatly appreciated though!