Chuck D. Bones

Circuit Wizard

Here's how I do it. Whether I use my own Vero design or somebody else's, the process is the same. We're going on the assumption that the Vero design has already been checked for correctness. Each step ends with an inspection or test. If anything is wrong, fix it before proceeding to the next step.

1. Mark the Vero board for cutting to size. Recheck the marking. Cut the board to size. I clamp the board in a vise with the line where I'm going to cut just above the jaws. I score the board on both sides and then break it. After that I clean up the rough edges and sharp corners with a grinder. check that the board is the right size and the strips are oriented correctly. I screwed this up once.

2. Mark the board for cutting the strips. I use a fat sharpie. Then I recheck the marking. Keep in mind that most views of the Vero are from the top and the cutting happens on the bottom, so you have to reverse the pattern. I use a drill press with a #28 drill to make the cuts. I set the drill stop so I drill just deep enough to make a clean cut. I used to to it by hand with a pin vise. With a drill press, I can make all of the cuts in the time it took to make just one by hand. Check the board visually to verify all of the cuts are in the right places and there is no conductive debris that could cause shorts. Check each cut with a DMM to ensure the cut is complete.

3. Install the jumpers. Inspect.

4. Install ICs or IC sockets. Inspect.

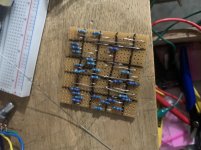

5. Install resistors. Inspect.

6. Install diodes. Inspect. (notice a trend here?)

7. Install transistors (or sockets). Inspect.

8. Install non-electro caps. Inspect.

9. Install electro caps. Inspect.

10. Perform a thorough inspection of the solder side, looking for shorts between strips.

11. Attach power wires. Install socketed parts. Power it up and check DC voltages.

12. Power off and wire up the rest of the board including switches, pots & jacks. Inspect to make sure all of the wires are in the correct location and there are no shorts where you just soldered. Connect a guitar (or sig gen or looper) to the input, connect and amp or scope to the output and run an end-to-end test. Verify all pots and switches work as expected.

13. Box it & rock it!

1. Mark the Vero board for cutting to size. Recheck the marking. Cut the board to size. I clamp the board in a vise with the line where I'm going to cut just above the jaws. I score the board on both sides and then break it. After that I clean up the rough edges and sharp corners with a grinder. check that the board is the right size and the strips are oriented correctly. I screwed this up once.

2. Mark the board for cutting the strips. I use a fat sharpie. Then I recheck the marking. Keep in mind that most views of the Vero are from the top and the cutting happens on the bottom, so you have to reverse the pattern. I use a drill press with a #28 drill to make the cuts. I set the drill stop so I drill just deep enough to make a clean cut. I used to to it by hand with a pin vise. With a drill press, I can make all of the cuts in the time it took to make just one by hand. Check the board visually to verify all of the cuts are in the right places and there is no conductive debris that could cause shorts. Check each cut with a DMM to ensure the cut is complete.

3. Install the jumpers. Inspect.

4. Install ICs or IC sockets. Inspect.

5. Install resistors. Inspect.

6. Install diodes. Inspect. (notice a trend here?)

7. Install transistors (or sockets). Inspect.

8. Install non-electro caps. Inspect.

9. Install electro caps. Inspect.

10. Perform a thorough inspection of the solder side, looking for shorts between strips.

11. Attach power wires. Install socketed parts. Power it up and check DC voltages.

12. Power off and wire up the rest of the board including switches, pots & jacks. Inspect to make sure all of the wires are in the correct location and there are no shorts where you just soldered. Connect a guitar (or sig gen or looper) to the input, connect and amp or scope to the output and run an end-to-end test. Verify all pots and switches work as expected.

13. Box it & rock it!