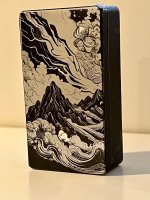

passtheducky

Active member

I still suck at waterslides. I could do the regular clear film ones fine, but I am now trying to use the film-free laserjet kind and I can't get the image to adhere to the enclosure.

Using Sunnyscopa Clear Film Free LaserJet paper in a Brother laser printer.

1. Yes, I'm printing the image on the right side of the paper

2. Applying a decent layer of that special W1+ glue

3. Yes, I'm putting the decal face down on the enclosure and the back comes off fine.

4. I tried using both a hair dryer and a heat gun to dry it. I tried a lot of heat, a little heat. Can you cook it too much here?

5. Whatever I do, the image peels off with the film instead of adhering to the enclosure.

Does this stuff not work on raw aluminum? I'm trying to do a design where the "white" is brushed aluminum coming through the non-printed parts.

Does the aluminum need a clear coat or something to make a smoother surface that I can stick to?

Using Sunnyscopa Clear Film Free LaserJet paper in a Brother laser printer.

1. Yes, I'm printing the image on the right side of the paper

2. Applying a decent layer of that special W1+ glue

3. Yes, I'm putting the decal face down on the enclosure and the back comes off fine.

4. I tried using both a hair dryer and a heat gun to dry it. I tried a lot of heat, a little heat. Can you cook it too much here?

5. Whatever I do, the image peels off with the film instead of adhering to the enclosure.

Does this stuff not work on raw aluminum? I'm trying to do a design where the "white" is brushed aluminum coming through the non-printed parts.

Does the aluminum need a clear coat or something to make a smoother surface that I can stick to?