brightlight

Active member

I have a very amateur question regarding something I recall reading in passing a while back concerning paint + rough edges inside of enclosures.

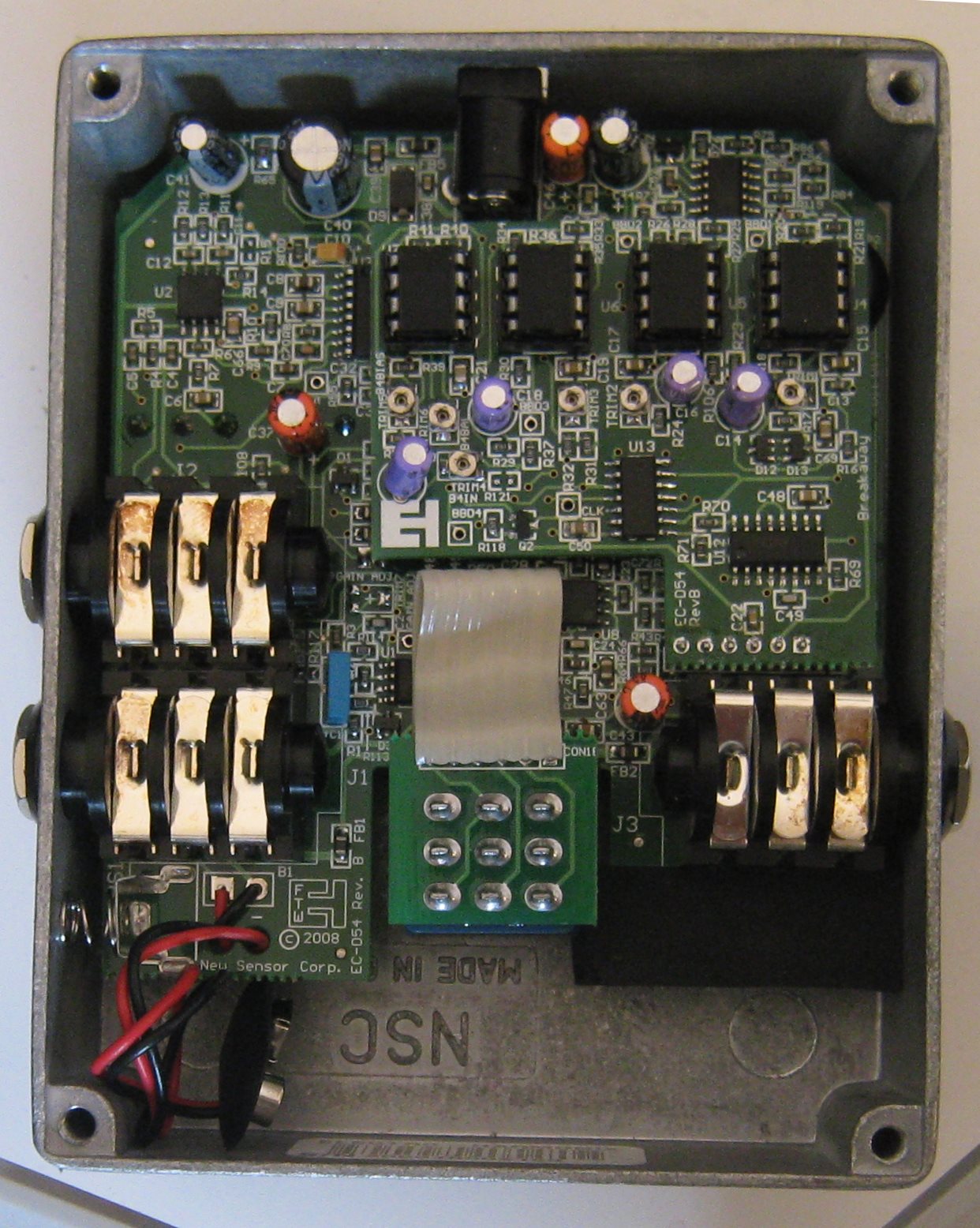

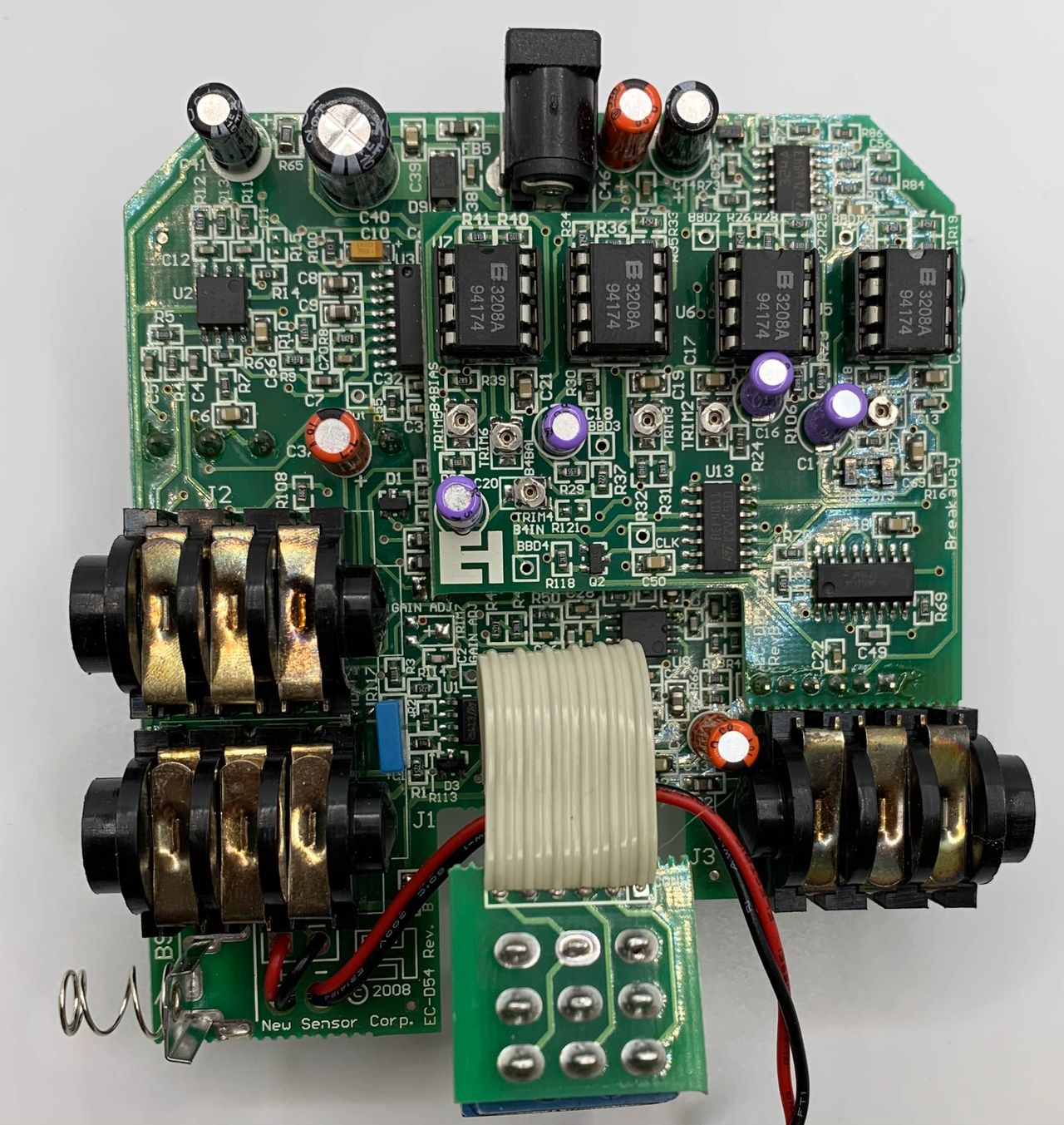

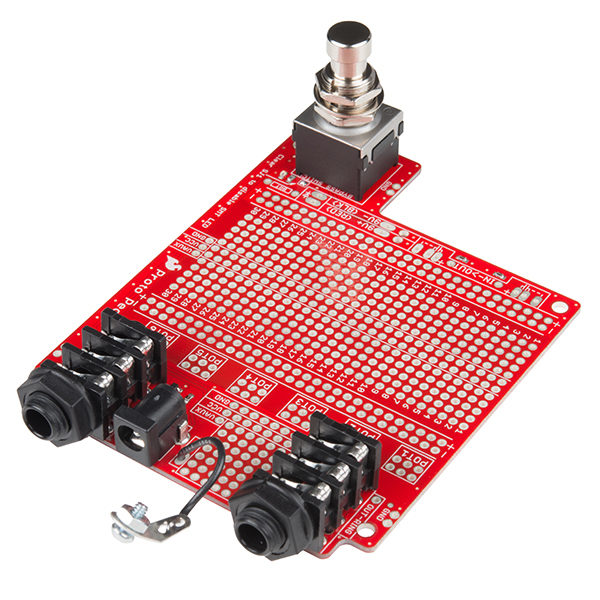

I recall reading that when you have for example a pre-drilled and powder coat painted enclosure from Tayda that the little bit of paint residue and rough inside edges can cause the I/O jacks, DC jack, and pots to have improper contact with the enclosure. I get it from a physical comfort stand point that those rough edges could make your jacks, etc not fit quite snug, but what is the logic behind these parts HAVING to make good physical contact with the enclosure?

I use those cheap commonly recommended plastic DC jacks from Tayda so I think i can rule out that this parts needs to make enclosure contact for grounding purposes, in fact I think you'd wanna avoid it since this seems to be a common issue for people using metal DC jacks.

But for the I/O jacks do they need to make perfect contact with the enclosure for grounding purposes somehow? Obviously the hot tip shouldn't be touching anything except the wire hooked up to it, but does the sleeve rely on enclosure contact for grounding?

I've read the basic workflow thread about 10 times at this point and I notice paint on the inside of that example enclosure. Is the the actual drill hole that needs to be completely free of paint or that entire internal backside of the enclosure?

Also does any of this apply to pots or only the other external components?

Thanks for your patience, I hope I was clear enough with my questions!

I recall reading that when you have for example a pre-drilled and powder coat painted enclosure from Tayda that the little bit of paint residue and rough inside edges can cause the I/O jacks, DC jack, and pots to have improper contact with the enclosure. I get it from a physical comfort stand point that those rough edges could make your jacks, etc not fit quite snug, but what is the logic behind these parts HAVING to make good physical contact with the enclosure?

I use those cheap commonly recommended plastic DC jacks from Tayda so I think i can rule out that this parts needs to make enclosure contact for grounding purposes, in fact I think you'd wanna avoid it since this seems to be a common issue for people using metal DC jacks.

But for the I/O jacks do they need to make perfect contact with the enclosure for grounding purposes somehow? Obviously the hot tip shouldn't be touching anything except the wire hooked up to it, but does the sleeve rely on enclosure contact for grounding?

I've read the basic workflow thread about 10 times at this point and I notice paint on the inside of that example enclosure. Is the the actual drill hole that needs to be completely free of paint or that entire internal backside of the enclosure?

Also does any of this apply to pots or only the other external components?

Thanks for your patience, I hope I was clear enough with my questions!