seangarland123

Member

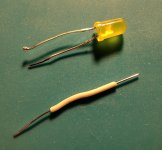

Hi all - I am just starting out in building my own pedals, and had a question regarding which side of the PCB you would solder the LED legs, or if it even matters (as long as you have the polarity correct)?

With the components side facing up while mounted, would I run the LED legs through the backside and solder on the components side, or wrap the LED legs around the components side and solder on the backside, as I’ve done with all the components?

EDIT: The LED I am asking about would be the LED mounted to the enclosure, indicating whether the pedal is engaged or off.

Thanks!

With the components side facing up while mounted, would I run the LED legs through the backside and solder on the components side, or wrap the LED legs around the components side and solder on the backside, as I’ve done with all the components?

EDIT: The LED I am asking about would be the LED mounted to the enclosure, indicating whether the pedal is engaged or off.

Thanks!

Last edited: