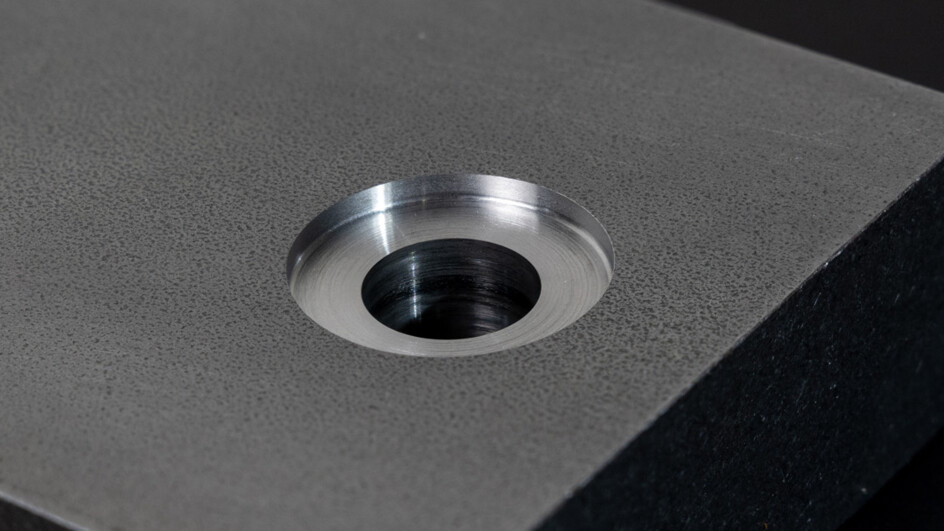

If you have a drill press, and either a vise or a good way to hold the enclosure, buy a cheap 1 inch end mill with a reduced shaft (so it fits in your chuck). The cast aluminum is very soft, and even a poor quality tool will cut it. (I hate telling anyone to buy a cheap tool!)

Set your stop to give you about 2.5 mm thickness, and feather the mill into the aluminum until it stops. Just approximate the center for each of the holes you’ve drilled.

It sort of amazes me that in their casting process there is so much variation in the wall thicknesses. I mean, I believe it, but there really shouldn’t be much variation in cast parts.

(edited to add reference to

@Feral Feline earlier post refering to this idea, and also to stress:

don’t do this with a hand held drill!)