mybud

Well-known member

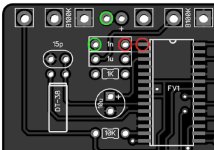

Ok, so this post relates to yesterday's Hydra build. You'll notice that I slightly borked the 100nF cap at top left of the gutshot.

I say this because of some weird behaviour as follows: In bypass, the LED glows dimly, which suggests TMM that it's still getting current from somewhere when it shouldn't. This is accompanied by a considerable pop when the pedal's engaged.

So question 1: is this cap related to the power supply as a filter which is now partly dysfunctional because of damage to the cap? If so, is there a simple workaround to fix this without removing the entire installation again? Reasoning immediately below.

I notice that the moar black switches don't like being removed from the housing and that there are already faint signs of wear to the switch finishes when doing so too many times. So I'm looking for a simple, minimally intrusive kludge to fix this if one of our gurus could advise. Adding a further pulldown resistor to the footswitch, or some such, if at all possible.

As in the build report, I plan to retouch one and two of the 'drum' switches, where my half-baked soldering (long layoff, chops need improving) clearly shows room for improvement. For now, I can live with the pop and enjoy the 'creative' fun aspects of the pedal but I will eventually want to fix these issues.

Thanks in advance, any advice gladly received. And please @Robert, kindly provide the schematic when time permits.

I say this because of some weird behaviour as follows: In bypass, the LED glows dimly, which suggests TMM that it's still getting current from somewhere when it shouldn't. This is accompanied by a considerable pop when the pedal's engaged.

So question 1: is this cap related to the power supply as a filter which is now partly dysfunctional because of damage to the cap? If so, is there a simple workaround to fix this without removing the entire installation again? Reasoning immediately below.

I notice that the moar black switches don't like being removed from the housing and that there are already faint signs of wear to the switch finishes when doing so too many times. So I'm looking for a simple, minimally intrusive kludge to fix this if one of our gurus could advise. Adding a further pulldown resistor to the footswitch, or some such, if at all possible.

As in the build report, I plan to retouch one and two of the 'drum' switches, where my half-baked soldering (long layoff, chops need improving) clearly shows room for improvement. For now, I can live with the pop and enjoy the 'creative' fun aspects of the pedal but I will eventually want to fix these issues.

Thanks in advance, any advice gladly received. And please @Robert, kindly provide the schematic when time permits.